The Specialists in 5-Axis Machining Centers for High Performance Machining

Bavius Technologie GMBH has been one of the world’s leading manufacturers of 5-axis high performance machining centers for more than 30 years. We offer standardized machine concepts with a modular design to be flexible in finding the optimum solution for your machining requirements. Thanks to a large number of automation solutions, we ensure a unique versatility for a wide range of applications.

Horizontal Machining Centers HBZ

Horizontal machining centers for precise machining with the highest chip removal rates. Excellent productivity combined with small footprint.

APPLICATION DIVERSITY

With its HBZ AeroCell, HBZ CompactCell and HBZ Trunnion series, Bavius offers a product line that stands for short machining times as well as optimum machining strategies and quality. The machines in the HBZ AeroCell and HBZ CompactCell series are predestined for cutting-intensive 5-axis machining of aluminium and cover a wide range of applications to workpiece sizes up to a length of 7,000 mm and width of 3,000 mm.

The HBZ Trunnion series additionally extends the material spectrum by hard-to-machine materials such as steel and titanium and allows machining for small parts with an interference contour of less than 1,000 mm up to 1,700 mm.

IDEAL MACHINING CONDITIONS

The intrinsically rigid machine design ensures stable and precise machining even at high travel speeds and accelerations. The horizontal spindle position guarantees optimum chip and coolant management without recutting.

OPTIMUM ERGONOMICS

Bavius horizontal machining centers ensure high user friendliness thanks to their intelligent design: good visibility into the workzone during the machining process as well as loading and unloading take place ergonomically in a horizontal table position.

- Horizontally positioned spindle and optimum chip management

- Highly-dynamic 5-axis simultaneous machining

- High material removal rate and productivity

- Significant reduction in machining times and costs per piece

- Stable, intrinsically rigid machine design

- Compact machine design with low space requirement

- No special foundation required

- Fully enclosed workzone

- Optimum values for power and precision

- Numerous options for automation available

The HBZ product line comprises three machine series with different technological highlights and sizes. The horizontal machining concept allows us to cover a wide range of applications in 5-axis cutting. We provide the optimum machine for your specific application!

| HBZ AeroCell | HBZ CompactCell | HBZ Trunnion | |||

| Table or Pallet Size | max. 7,000 x 2,000 mm

max. 5,000 x 2,500 mm |

max. 4,000 x 1,000 mm | max. 1,600 mm Diameter

max. 1,250 x 1,650 mm |

||

| Axis Travel (X,Y,Z) | max. 7,800 / 2,500 / 700 mm | max. 4,650 / 1,100 / 550 mm | max. 1,670 / 1,350 / 1,100 mm | ||

| Travel Speed (X,Y,Z) | max. 80 / 80 / 80 m/min | max. 60 / 40 / 60 m/min | max. 60 / 60 / 60 m/min | ||

| Spindle Data | Power: max. 156 kW

Speed: max. 30,000 RPM Torque: max. 100 Nm |

Power: max. 81 kW

Speed: max. 30,000 RPM Torque: max. 67 Nm |

Power: max. 156 kW

Speed: max. 30,000 RPM Torque: max. 1,010 Nm |

||

Profile Machining Centers PBZ

Flexibility and High Performance for 6-sided Profile

APPLICATION DIVERSITY

Different lengths, technological highlights as well as differences in design: With its PBZ HD, PBZ NT and PBZ SC series, Bavius offers profile machining centers for all profile cutting applications. In light or heavy extrusions, solid material, short and narrow as well as long and wide profiles up to 30,000 mm, complex tasks are performed in aluminum and steel. In all cases, the profile machining centers guarantee highly dynamic and economical cutting to meet high quality demands.

PRECISION AND POWER

The combination of a rigid machine design, good ergonomics and powerful machining units guarantees precise and powerful 5-axis simultaneous machining. The profile machining centers from Bavius allow you to realize short machining times and low costs per piece as well as excellent precision.

INNOVATIVE CLAMPING TECHNOLOGY

Individually configurable clamping vice and table variants make it possible to realize a wide range of solutions for flexible workpiece clamping. 6-side complete machining is also possible through end machining.

- Powerful HPC/HSC machining of a wide range of profile types

- Highly dynamic 5-axis machining of aluminum and steel

- Freely positionable clamping vices permit interference-free machining

- Set production: Production of entire part sets (e.g. complete door frames) from one workpiece thanks to vice shifting

- 5-axis simultaneous machining

- 6-side complete machining

- Solid machine construction for stable and precise machining

- Numerous options for automation

The PBZ product line comprises three machine series with different technological highlights and sizes. This allows us to cover a wide range of applications in 5-axis cutting of profiles and to provide the optimum machine for your application in profile machining.

| PBZ HD | PBZ NT | PBZ SC | |||

| Work Piece Length | max. 30,000 mm | max. 25,000 mm | max. 24,000 mm | ||

| Work Piece Cross-section (W x H) | max. 800 x 300 mm (clamping version)

max. 800 x 575 mm (table version) |

max. 600 x 300 mm | max. 800 x 500 mm (5-Axis)

max. 1,200 x 550 mm (3-Axis) max. 400 x 300 mm (clamping vice version) max. 800 x 500 mm (table version) |

||

| Axis Travel (X,Y,Z) | max. 1,500 / 1,000 mm | max. 1,000 / 850 mm | max. 1,000 / 720 mm | ||

| Travel Speed (X,Y,Z) | max. 70 / 40 / 40 m/min | max. 90 / 55 / 55 m/min | max. 70 / 55 / 55 m/min | ||

| Spindle Data | Power: max. 81 kW

Speed: max. 30,000 RPM Torque: max. 75 Nm |

Power: max. 37 kW

Speed: max. 28,000 RPM Torque: max. 41 Nm |

Power: max. 37 kW

Speed: max. 28,000 RPM Torque: max. 41 Nm |

||

High Moving Portal Machining Centers GANTRY

High moving portal machining centers with moving Y-Bridge for dynamic and stable machining of large-volume lightweight and heavy work pieces.

STABLE VERTICAL MACHINING

A machine concept that permits both dynamic 5-axis simultaneous machining of large workpieces as well as heavy-duty cutting and HPC machining with high torques? The GANTRY product line successfully achieves this with two machine series and a high level of modularization: The GANTRY HD is the specialist for dynamic machining and high speed cutting in aluminum. In contrast, the GANTRY SD features very large drives and guide rails for stable and efficient high performance machining of aluminum and heavy-duty cutting of steel and titanium. The intrinsically rigid machine design with high moving Y-bridge guarantees highly precise machining on table sizes up to 47,000 x 7,000 mm in both variants.

CUSTOMIZATION

Both series of the high moving portal machining centers can be flexibly customized by means of a wide range of options and optimally adapted to your requirements. Two special configurations are particularly worth highlighting: the configuration with double portal (DP) and the configuration with two spindles (TS).

- Precise 5-axis simultaneous machining

- Intrinsically rigid machine design with high moving Y-bridge

- Dynamic machining and high speed cutting in aluminum

- High performance machining of aluminum as well as heavy-duty cutting of steel and titanium

- Machining of large-volume and large workpieces

- Customer-specific configuration of table sizes, floor height and clamping concept

- Special configurations possible: Double portal (DP) and twin spindle (TS)

- Modular machine design for maximum flexibility thanks to many options

The GANTRY product line comprises two machine series with different technological highlights and sizes. This allows us to cover a wide range of applications in 5-axis high moving portal machining centers and to provide the optimum machine for your application.

| GANTRY SD | GANTRY HD | ||||

| Table Size | Table Length: 4,000 to 47,000 mm

Table Width: max. 7,000 mm |

Table Length: 4,000 to 47,000 mm

Table Width: max. 4,000 mm |

|||

| Axis Travel (X,Y,Z) | max. 47,500 / 6,700 / 2,200 mm | max. 47.500 / 4,500 / 1,500 mm | |||

| Travel Speed (X,Y,Z) | max. 50 / 50 / 30 m/min | max. 60 / 60 / 60 m/min | |||

| Spindle Data | Power: max. 187 kW

Speed: max. 30,000 RPM Torque: max. 600 Nm |

Power: max. 81 kW

Speed: max. 30,000 RPM Torque: max. 75 Nm |

|||

Universal Machining Centers UBZ

Modular universal machining centers for flexibility and highly-precise machining of work pieces up to 12 x 2 m.

STABLE VERTICAL MACHINING

Dynamic HSC machining of aluminum with high speeds and power as well as powerful HPC machining of aluminum and heavy-duty cutting of steel and titanium with high-torque spindles: The machines in the UBZ product line are universally suitable thanks to machine designs and configurations tailored specifically to these applications. The differences between the UBZ SD and UBZ HD are based on the materials that can be machined. This in turn is the result of the specific configurations of the guide rails and drives as well as the rigidity of the machines and suitable spindles. The 5-axis UBZ universal machining centers guarantee precise and productive machining of workpieces up to 12,000 x 2,000 mm.

CUSTOMIZATION

Thanks to their modular design and a wide range of options, both series of the universal machining centers can be flexibly customized and optimally adapted to your requirements. Individual automation concepts round off the modular and customer-specific machine concept.

- Rigid machine design with fixed portal for precise machining

- 5-axis simultaneous machining

- Powerful “heavy-duty” HSC machining of aluminum

- Heavy-duty cutting of titanium and steel as well as HPC machining of aluminum

- Modular machine design for customer-specific adaptation to production processes and material requirements

- Full enclosure of the workzone

- Large number of different automation solutions and options available

The UBZ product line comprises two machine series with different technological highlights and sizes. This allows us to cover a wide range of applications in 5-axis cutting and to provide the optimum machine for your application.

| UBZ SD | UBZ HD | ||||

| Table Size | Table Length: 2,500 to 12,500 mm

Table Width: 1,000 to 2,000 mm |

Table Length: 2,500 to 12,500 mm

Table Width: 1,000 to 2,000 mm |

|||

| Axis Travel (X,Y,Z) | max. 14,000 / 2,700 / 1,500 mm | max. 14,000 / 2,800 / 1,500 mm | |||

| Travel Speed (X,Y,Z) | max. 40 / 40 / 40 m/min | max. 60 / 60 / 60 m/min | |||

| Spindle Data | Power: max. 187 kW

Speed: max. 30,000 RPM Torque: max. 600 Nm |

Power: max. 81 kW

Speed: max. 30,000 RPM Torque: max. 75 Nm |

|||

Automated Solutions

With the numerous available options. We jointly find the optimum automation solution for your individual processes. Increased productivity and a reliable production are the goals.

YOUR ADVANTAGES THROUGH AUTOMATION

- Increased productivity

- Optimized processes and process reliability

- Guaranteed flexibility

- Loading and unloading parallel to production

- Reduced non-productive times, cycle times

- Unmanned operation

- Modularly extendable automation solutions

- Machine and automation from one source

- Reduced costs per piece

- Sustainable future continuity

- Customised and standardised solutions

- Pallet changing system for two pallets

- Pallet automation on rail system

- Pallet automation with pallet rack

- Material handling and secondary operations with robot assistance

- Portal handling system

- Linking of several machines

- Other options on specific customer request

Options

Modular machines and an extensive range of options. In different areas make it possible to customize all Bavius Machining Centers. Configure your machining center optimally for your needs.

- Diversity of spindles

- Tool magazines of different capacity and tool length

- Minimum quantity lubrication

- Cooling lubricant systems

- Chip disposal

- Extraction systems

- Clamping devices

- and much more

MEASUREMENT, INSPECTION, CONTROL

- Touch probe

- Tool measurement and control

- Spindle monitoring

- Temperature compensation linear

- Temperature compensation spindle

- Linear and rotational axis measurement and adjustment

- Camera surveillance

- Accuracy packages

- and much more

- Telediagnosis

- Tool management

- Measuring cycles

- Machine data monitoring

- Process data monitoring

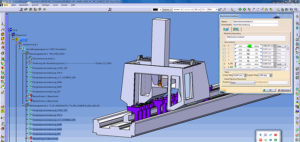

- 3D machine models

- Post processors

- Simulation models

- and much more