Nomura Swiss Turning

Know Worldwide for Extreme Rigidity + Process Stability

When you need to:

- Machine complex parts

- Work with difficult materials

- Achieve fine surface finishes

- Get unprecedented tool life

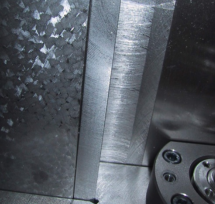

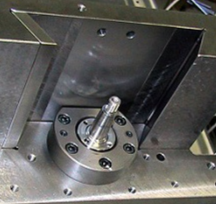

Hand-Scraped Ways

Maintain high levels of accuracy

Dovetail Slides

Add strength and rigidity

Large Ball Screws

Reduce friction and ensure smooth machining

Heavy Full Length Base

Ensure complete process stability

X-Series

NN-3X

Specialized for minature and high-precision parts

The best tool layout among equivalent models

It has the largest number of tools at 17 and a drastically shortened cycle time.

Expanded tool options

| NN-3X | |||||

| Max. Stock Diameter(mm): | 3 | ||||

| Main Spindle Power(KW): | 1.1/0.75 | ||||

| Main Spindle(RPM): | 20,000 | ||||

| Sub Spindle Power(KW): | 1.1/0.75 | ||||

| Sub Spindle(RPM): | 20,000 | ||||

| Tool Capacity: | 17 | ||||

| Number of Axes(C1, C2 Excluded): | 4 |

NN-10EX2

Specialized for high-precision and complicated machining under 10mm

Improved productivity (Shortened cycle time)

Built-in Main & Sub

The latest NC “Mitsubishi M80”

| NN-10EX2 | |||||

| Max. Stock Diameter(mm): | 10 | ||||

| Main Spindle Power(KW): | 3.7/1.5 | ||||

| Main Spindle(RPM): | 15,000 | ||||

| Sub Spindle Power(KW): | 1.1/0.75 | ||||

| Sub Spindle(RPM): | 15,000 | ||||

| Tool Capacity: | 22 | ||||

| Number of Axes(C1, C2 Excluded): | 5 |

SB-Series

The S Series is a compact Swiss-type CNC automatic lathe possessing unrivaled machining capabilities and interchangeability to handle almost any precision turning operations.

NN-16SB6

16SB6 comes standard with 5 OD turning tools, 3 live mill/drill tools, 3 main/back end working tools and full C-Axis on both spindles. An optional interchangeable 4 position cross drill attachment, Polygon cutting A or B attachment, hob cutting and 3 position cross drill attachment can be mounted in place of the live tools to add flexibility to your machine.

Specialized for simple parts under 16mm

High-efficiency, reasonable price

Foldable door for user convenience

| NN-16SB6 | |||||

| Max. Stock Diameter(mm): | 16 | ||||

| Main Spindle Power(KW): | 2.2/1.5 | ||||

| Main Spindle(RPM): | 10,000 | ||||

| Sub Spindle Power(KW): | 0.75/0.3 | ||||

| Sub Spindle(RPM): | 7,000 | ||||

| Tool Capacity: | 16 | ||||

| Number of Axes(C1, C2 Excluded): | 4 |

NN-16SB7

16SB7 comes standard with 5 OD turning tools, 3 live mill/drill tools, 4 main/back end working tools and full C-Axis on both spindles, 2 live and 2 static tools work independently on the sub-spindle side. An optional interchangeable 4 position cross drill attachment, polygon cutting A or B attachment, hob cutting and 3 position cross drill attachment can be mounted in place of the live tools to add flexibility to your machine.

Specialized for complicated shape parts under 16mm

Sub tool post and X2 axis for back machining

Slant type tool post for easy chip removal

Slotting machining on sub-spindle (option)

| NN-16SB7 | |||||

| Max. Stock Diameter(mm): | 16 | ||||

| Main Spindle Power(KW): | 2.2/1.5 | ||||

| Main Spindle(RPM): | 10,000 | ||||

| Sub Spindle Power(KW): | 0.75/0.3 | ||||

| Sub Spindle(RPM): | 7,000 | ||||

| Tool Capacity: | 20 | ||||

| Number of Axes(C1, C2 Excluded): | 5 |

J-Series

The J machines provide standard machining capabilities normally found on larger machines. It comes standard with independent slides for both the main spindle and back spindle, full C-axis on both spindles and field installable options to allow the machine configuration to change with your part requirements. The standard 3 eccentric live tools add a normally optional capability to help provide a one setup complete part operation. A variety of options are available which include a front eccentric drill unit and various combinations of turning and mill/drill units for the back spindle.

NN-20J3 / NN-20J3XB

20J3 is a highly flexible machine with a sub-spindle that comes standard with 6 O. D. tools, 4 static front/back drilling stations and 5 live cross drill/mill spindles for the main spindle. The sub- spindle has 3 static back drilling tools, 2 O. D. tools, 3 live cross drill/mill tools and 3 live off-center drill/mill tools. Both the main and back spindles come standard with a .001 degree C-Axis.

NC controller selectable

Mitsubishi, Fanuc

The best tool layout among equivalent models

For complicated shape parts

Shortened cycle time

Expanded tool options

Specialized for high-precision parts

Horizontal tool post

Dovetail structure

B axis control (0-135 Degree rotation)(Option)

Drilling, tapping, end-mill

| NN-20J3 | NN-20J3XB | ||||

| Max. Stock Diameter(mm): | 16/20 | 20 | |||

| Main Spindle Power(KW): | 3.7/1.5 | 3.7/1.5 | |||

| Main Spindle(RPM): | 10,000 | 10,000 | |||

| Sub Spindle Power(KW): | 3.7/1.5 | 3.7/1.5 | |||

| Sub Spindle(RPM): | 10,000 | 10,000 | |||

| Tool Capacity: | 30 | 29 | |||

| Number of Axes(C1, C2 Excluded): | 6 | 7 |

U-Series

The U series of machines are built for high precision part capability where a back spindle is not required. A variety of options are available which include a front eccentric drill unit, a 3 spindle face mill/drill and 2 spindle cross drill mill unit and a .001 degree main spindle C-axis.

NN-20/25U5

The 20U5 or 25U5 comes standard with 5 OD tools, 4 stationary end-working tools, 4 live cross drilling/milling spindles with .001 degree C-Axis. A variety of options are available which include a 3 spindle face off center drilling unit drill/mill & 2 spindle cross drill/mill unit.

A 5 spindle cross drilling unit is also available.

| NN-20/25U5 | |||||

| Max. Stock Diameter(mm): | 20/25 | ||||

| Main Spindle Power(KW): | 3.7/2.2 | ||||

| Main Spindle(RPM): | 10,000 | ||||

| Tool Capacity: | 13 | ||||

| Number of Axes(C1, C2 Excluded): | 3 |

UB-Series

The X and Y axis capabilities with 1 OD turning and 3 ID tools for the back spindle allows completing complex parts. A variety of options are available which include a front eccentric drill unit with a 3 spindle face mill/drill and 2 spindle live back working.

NN-20/25UB8(K)

20\25UB8 comes standard with 5 OD turning stations, 4 non rotating drilling positions which can be double tooled for back-working operations, 4 live spindles for cross drilling/milling, main and sub-spindle C-Axis. For parallel processing the sub-spindle controlled by X2 and Z2 has 2 additional OD/ID positions plus 2 live spindles. It can be synchronized with the main spindle.

A variety of options are available which include a face off center 3 positions drilling unit, guide bushless system (chucker kit) and long part guiding device.

NC controller selectable

Mitsubishi, Fanuc

Expanded tool options

Eccentric turning operation on sub tool

Guide/Non-guide bush type

Minimized remaining material (Non-guide bush type)

Specialized for high-precision parts

High-efficiency, reasonable price

| NN-20/25UB8(K) | |||||

| Max. Stock Diameter(mm): | 20/25 | ||||

| Main Spindle Power(KW): | 3.7/2.2 | ||||

| Main Spindle(RPM): | 10,000 | ||||

| Sub Spindle Power(KW): | 1.5/0.55 | ||||

| Sub Spindle(RPM): | 6,000 | ||||

| Tool Capacity: | 21 | ||||

| Number of Axes(C1, C2 Excluded): | 5 |

NN-32UB8K2

The best selling model

Horizontal tool post

Dovetail structure

Efficient tool layout

Shortened cycle time

High-efficiency, reasonable price

| NN-32UB8K2 | |||||

| Max. Stock Diameter(mm): | 32 | ||||

| Main Spindle Power(KW): | 5.5/3.7 | ||||

| Main Spindle(RPM): | 8,000 | ||||

| Sub Spindle Power(KW): | 3.7/1.5 | ||||

| Sub Spindle(RPM): | 6,000 | ||||

| Tool Capacity: | 23 | ||||

| Number of Axes(C1, C2 Excluded): | 5 |

NN-38UB8K2

The latest NC “Mitsubishi M80”

New Model

For complicated shape parts

Shortened cycle time

Long drill

Specialized for high-precision parts

Horizontal tool post

Dovetail structure

| NN-38UB8K2 | |||||

| Max. Stock Diameter(mm): | 38 | ||||

| Main Spindle Power(KW): | 7.5/5.5 | ||||

| Main Spindle(RPM): | 8,000 | ||||

| Sub Spindle Power(KW): | 5.5/3.7 | ||||

| Sub Spindle(RPM): | 8,000 | ||||

| Tool Capacity: | 26 | ||||

| Number of Axes(C1, C2 Excluded): | 5 |

YB3-Series

The YB23series of machines offer a high degree of adaptability with independent slides for the main and back-spindles to increase productivity and the machining of highly complex parts. The machine configuration can easily be modified on site to accommodate production requirements. The main and sub-spindle have standard full C axis and are independently temperature controlled. A variety of options are available which include a front and back eccentric drill unit, and various combinations of turning and mill/drill units.

NN-32YB3 / NN-32YB3XB

32YB3 is a highly flexible sub-spindle machine with 5 OD tools, 4 static front/back end working tools and 6 live cross drill/mill tools for the main spindle. The back comes standard with 3 static end working tools, 2 OD tools and 2 live drill/mill tools. Both the main and back spindles come standard with a .001 degree C-Axis.

A variety of options are available which include a front and back eccentric drill unit, and various combinations of turning and drill/mill units.

Competitive tooling capacity

Maximized number of tools (sub tool post)

The best selling model

Horizontal tool post

Dovetail structure

Specialized for complicated shape parts

Expanded tool options

Minimized heat deformation and vibration

Integrated casting bed

| NN-32YB3 | NN-32YB3XB | ||||

| Max. Stock Diameter(mm): | 25/32 | 32 | |||

| Main Spindle Power(KW): | 5.5/3.7 | 5.5/3.7 | |||

| Main Spindle(RPM): | 8,000 | 8,000 | |||

| Sub Spindle Power(KW): | 3.7/1.5 | 3.7/1.5 | |||

| Sub Spindle(RPM): | 8,000 | 8,000 | |||

| Tool Capacity: | 30 | 39 | |||

| Number of Axes(C1, C2 Excluded): | 6 | 7 |

DST-Series

Rigid, precise and fast mill/tap center, available with several options.

DST 40A

The Mill/Tap Center that deserves the NomuraSwiss name. A combination of rigidity, accuracy and speed for ultimate productivity. The machine features a 15,000 rpm spindle, a 14 position random memory tool changer and a table travel of 16″ – 20″.

This machine is available with a number of options and accessories to customize the configurations to suit the application.

| DST 40A | |||||

| Table Size (mm): | 650 x 400 | ||||

| Spindle (RPM): | 15,000 | ||||

| Tool Capacity: | 14 | ||||

| Holder Type: | 7/24 taper NT30 | ||||

| Spindle Power (KW): | 2.2/3.7 | ||||