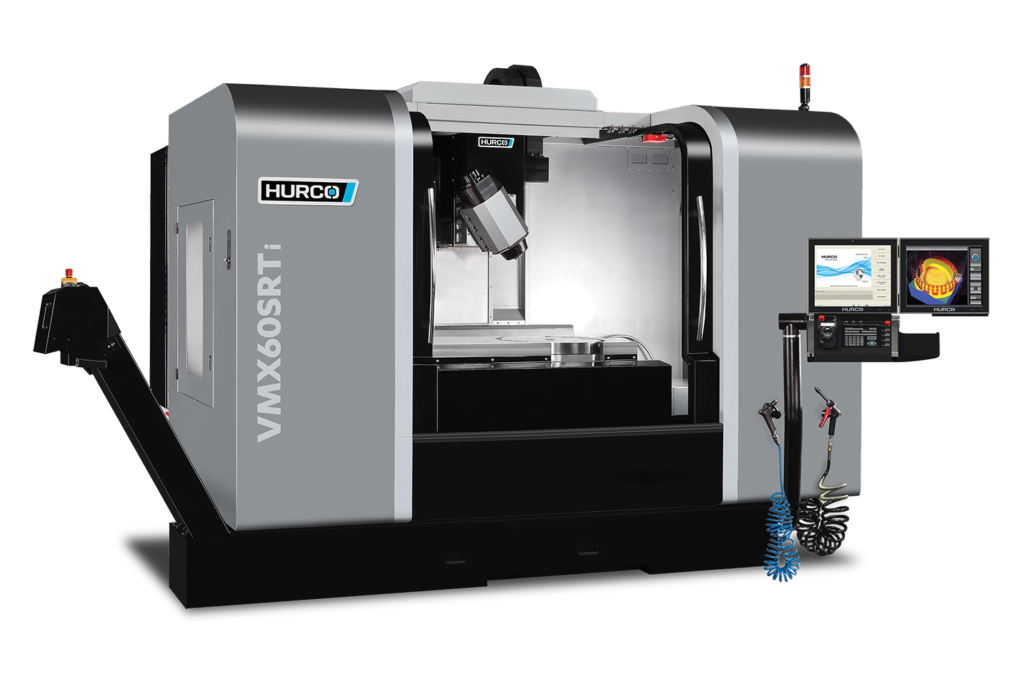

Hurco VMX60SRTi

5-Axis Vertical Machining Center

5-Axis CNC Mill Offers Maximum Flexibility

The Hurco VMX60SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Main Specs:

- Travel: 60″ x 26″ x 24″

- Table Size: 66″ x 26″ with 23.6″ Rotary Table

- Spindle: 12,000 RPM, 87 ft/lbs

- Tool Capacity: 40 CAT40

- Machine Weight: 20,000 lbs

Benefits of the SR 5-Axis Mill

The design of the swivel head 5-axis machining center makes the SR the best choice for certain applications.

Versatility. The large rotary table provides versatility that allows you to use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Better chip control. With the swivel head/rotary table configuration, you can run the machine horizontally and gain better chip control.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

Advanced 5-Axis Control Technology

Hurco has a host of many features designed to make 5-sided and 5-axis more efficient.

- Tool Center Point Management eliminates the need to account for the machining center’s centerlines of rotation. Instead, you simply use the solid model zero location. Post the program independent of where the stock is fixtured on the table.

- Transform Plane calculates the other locations for each of the rotary moves after you locate part zero. The control software only needs you to define part zero one time, and it figures out all of the other part zero locations automatically.

- 3-D Tool Compensation eliminates the need to repost the program in order to adjust the tool diameter because of wear. For 3D surfaces, machinists cut off the tool’s centerline to obtain a better surface finish and preserve tool life. This feature allows you to compensate for wear without the need to repost.

- Tool Path Linearization eliminates gouging of the workpiece and the line segments in the form of XYZBC or AC moves that a CAM system uses, which results in a smoother surface finish and a smaller program.

- Tool Vector Input allows the control to compute machine angles and positions, and calculates the angle the tool is going to tilt from the contact point of the surface. This means the part program is machine independent.

- Tool Vector Retract tells the spindle to retract out of the hole or pocket along the tool vector angle, which eliminates tool breakage and/or damage to the part.

We OWN 5-Axis + 5-Sided

At Hurco, we are immersed in 5-axis technology. We have carved out a niche in this arena because we made a commitment fifteen years ago to focus on 5-axis. We determined this type of machining center, combined with the capabilities of our control, would make our customers more profitable. Similar to the transition from manual mills to CNC mills, we believe the time is right for shops across the country to increase profit margin by investing in 5-axis.

Because we listened to our customers’ reservations about switching from a 3-axis process to 5-axis, we assembled a 5-axis applications team with a dedicated phone number and email to help. If you do NOT OWN a 5-axis machining center, the most important message you need to know: 5-sided machining on a 5-axis machining center will increase the profit margin of the parts you are producing on your 3-axis machining centers. The Hurco control makes programming easy for 5-sided—NO CAM needed!

Don’t Get Left Behind

According to benchmark data from Modern Machine Shop magazine, 24% of the highest performing shops in the U.S. are using 5-axis positioning. Hurco has carved out a niche in the 5-axis arena due to years of research and development. When we decide where to invest our resources at Hurco, our primary criteria are customer productivity and profitability. We evaluate the past, the present, and the possibilities of the future to determine what technology will benefit our customers the most. Nearly a decade ago, we determined that 5-axis machining warranted our attention and set a path to become the experts. We continue to lead the industry in developing control technology that optimizes the process for full 5-axis and 5-sided (3+2).

As our industry transitioned from manual to CNC milling, many shops got left behind. The transition from 3-axis to 5-axis may prove to be a similar situation. At the very least, you should evaluate the benefits of integrating 5-sided processes into your operation. With 5-sided, also called 3+2, you reduce setup time, increase accuracy, and expand your shop’s capability for future simultaneous 5-axis work.

When you invest in a Hurco 5-axis CNC machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center via powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

Features

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Standard

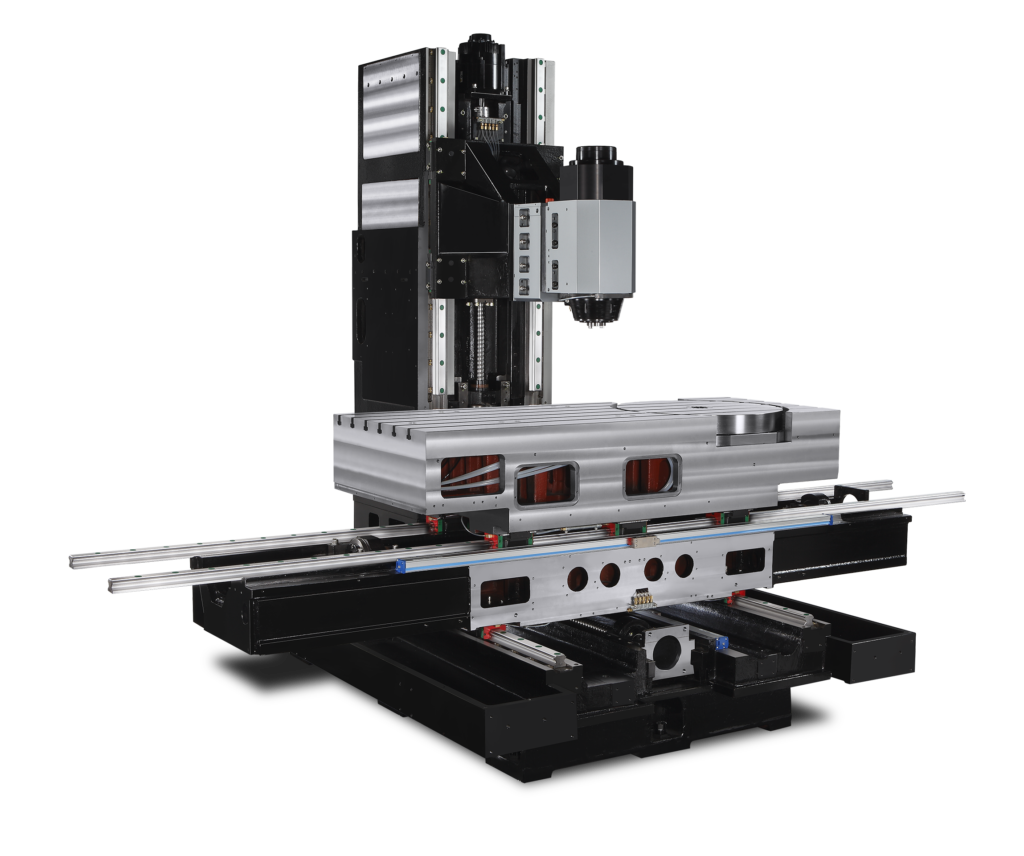

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- Wedge-locked Heavy duty Linear Rails for All Three Axes

- Direct Drive Z axis with Regenerative Brake – No Counterbalance

- Motorized, Liquid Cooled Spindle Design

- Double-Nut Pre-Tensioned Ballscrews Anchored at Both Ends

- 12,000 RPM Dual-wound Yaskawa AC Spindle Motor

- Angular Encoders, B/C Axis

- Yaskawa Sigma V Digital AC Servos

- Fast 1,181 ipm Rapid Traverse Rates (X,Y) 787 ipm on Z

- Electric Swing-arm 40 Station ATC – Random Access

- 4 Second Tool-to-Tool ATC Time

- Full Enclosure with Wide Front Access Doors

- Right and Left Side LED Work Lights

- Door Safety Interlocks / ANSI B11.23

- Powerful Enclosure Washdown System

- Pistol-style Coolant and Air Guns

- Metal Telescopic Way Covers

- Lift-Up Chip Conveyor

- Automatic Central Lubrication System

- Power Cabinet Heat Exchanger

- Way Lube Separation System

- Spindle Thermal Chiller Assembly

- Modular One-Piece ITX Control Rack

- 2.7GHz Dual Core Processor

- 4GB RAM Memory

- 128GB Solid State Hard Drive

- 12 Months Parts and Labor Warranty (24 months Control and Drives)

Hurco VMX60SRTi Machine Specifications

| Travel | |

| X-Axis | 60″ |

| Y-Axis | 26″ |

| Z-Axis | 24″ |

| B-Axis (Swivel Head) | +/-90º |

| Table | |

| Dimensions | 66″ x 26″ |

| Max Load | 3,000 lbs |

| Rotary Dia. | 23.6″ |

| Max Load | 1,100 lbs |

| C-Axis Motion | 360º |

| Spindle | |

| Spindle Type | |

| Spindle Speed | 12,000 RPM |

| Spindle Torque | 87 ft/lbs |

| Spindle Motor | 48 HP |

| Coolant Thru Spindle | Optional |

| Spindle Taper | CAT40 |

| Feed Rate | |

| Rapid Traverse (X/Y/Z) | 1,181/1,181/787 ipm |

|

B-Axis/C-Axis |

50/100 RPM |

| ATC | |

| Capacity | 40 Tools |

| Max. Tool Diameter | 2.95″ |

| Max. Tool Length | 9.8″ |

| Tool to Tool ATC Time | 4 seconds |

| Requirements | |

| Air Pressure | 5 CFM @ 80-100 psi |

| Power Consumption | 65 KVA |

| Machine Net Weight | 20,000 lbs |

| Operating Dimensions | 223.3” x 178.7” x 118.7” |