The most versatile CNC machines in the industry.

From 5-axis machining centers to large format machining centers designed for the aerospace and energy sectors, there is a Hurco CNC machine for you. Our flagship VMX line is the workhorse of 3-axis CNC machining centers. But we don’t stop at milling. We have worked diligently to ensure our turning centers are up to par with our mills. The TMX, TMM, and TM lines include a range of turning centers with chuck sizes up to 25 inches and mill turn machines that support the “done in one” philosophy.

Whether you are turning, milling, doing 2D parts or 3D parts, Hurco CNC machine tools, equipped with our integrated control, let you get down to the business of making chips faster than any other CNC machine tool.

Your expertise paired with our control technology—that’s mind over metal. That’s Hurco.

Hurco 50th Anniversary

Hurco Can Help

Expand Your Profit Power

5 Reasons to Buy Hurco

VM Series

Absolutely the best value on the market for small CNC machines

The Hurco VM CNC vertical milling machines offer powerful machining with a compact footprint, one-piece machine base, solid cast iron frame, Big Plus(r) spindle system, and the flexible Hurco CNC control with more memory and look-ahead than competitive models. The VM CNC machines are loaded with remarkably big capacity, productivity, and user flexibility.

Features

We use the same rigorous design and manufacturing processes for the VM CNC machining centers as we do on our high-end CNC machines. Our machine design uses a solidly built, one-piece machine base that uses premium components, such as heavy-duty linear rails in all three axes that are mounted to a machined shoulder to increase rigidity and wedge locked to reduce vibration instead of using the cheaper face-milled process.

The efficient design of the VM vertical machining centers results in a machine with a small footprint and large work cube. The MAX 5 CNC control comes standard with a 2.7GHz Dual-Core Processor, 4GB RAM Memory, 128GB Solid State Hard Drive, and 10,000 block lookahead. Additionally, the VM mills are equipped with a Big Plus 12,000 RPM Spindle system, and a 20-tool swing-arm ATC.

| VM10i | VM10HSi | VM20i | VM30i | |||

| Travels: | 26 x 16 x 20 in | 26 x 16 x 20 in | 40 x 20 x 20 in | 50 x 20 x 20 in | ||

| Table Size: | 30 x 16 in | 30 x 16 in | 46 x 20 in | 52 x 20 in | ||

| Spindle(RPM): | 12,000 | 20,000/30,000 | 12,000 | 12,000 | ||

| Tools: | 20 CAT 40 | 20 BT 30 | 20 CAT 40 | 20 CAT 40 |

VMX Series

CNC Mills Built for Performance Machining

The broad line of Hurco VMXi CNC machines are known by machinists as the industry workhorse. With the high velocities and accelerations of today’s applications, machine performance must be carefully optimized in order to maintain accuracy over extended periods of time. The Hurco VMXi Series of CNC mills delivers. It starts with a heavy, ribbed frame made of fine grain, high-grade cast iron. A dual-wound 12K spindle delivers the speed and cutting power that you need. For improved performance, the VMXDi models are equipped with a 15K inline direct-drive spindle that gives machinists outstanding surface finishes, faster tool changes, and improved thermal stability.

The roller ways on all Hurco VMXi vertical machining centers are larger with the Y-axis roller ways strategically spaced for increased strength and rigidity. The performance goes beyond the size and spacing of the ways. Instead of simply mounting the ways to a single surface, we wedge lock them to a machined shoulder, which makes the machine more rigid and robust. Additionally, we hand scrape or grind the mounting surfaces for increased accuracy. The multiple design and manufacturing details we incorporate into a Hurco VMC increase rigidity and reliability, which means each VMXi machining center will be the workhorse you expect.

Premium Components Increase Performance

We focus our efforts on reducing your overall cycle time while minimizing time wasted on non-cutting operations, by incorporating time-saving features in our VMX CNC mill design and using premium components.

The Heart of the Machining Center. The VMX CNC machining centers feature a powerful cartridge spindle with a low base-speed spindle that provides more torque for the machine without needing a gearbox, which eliminates additional assembly and maintenance. The VMXD CNC machines have a direct drive spindle that offers a higher rpm while still providing adequate torque for all machining needs.

Best-In-Class Chip Management High pressure, high volume, stainless steel coolant ring with adjustable nozzles delivers coolant right to the tool. Dedicated large capacity pump system and scraper type lift-up conveyor with barrel height discharge eliminate costly cleanup and save valuable time. A sloped telescopic way covers protect the internal components of the machining center.

Generous Tool Capacity ATC Fully enclosed, side-mounted, swing-arm ATC gives you more room to work and has more tool capacity. The all-electronic design provides the reliability, speed, and near-zero maintenance you require.

Prolonging Spindle Life + Preserving Accuracy. We have systems in place to prolong spindle life and combat spindle growth caused by heat dissipation. We use ceramic hybrid bearings in all VMX and VMXD spindles (12K and 15K for the VMXD CNC machines). These bearings run at much lower temperatures, so they have a significantly longer lifespan and a much lower probability of failure. They are packed with lifetime grease, which promotes a maintenance-free lubrication system. In addition to using ceramic bearings, we use a coolant jacket that is designed into the frame’s head casting to keep the spindle at an optimum temperature by stabilizing wide temperature variations and reducing heat dissipation. Because keeping the spindle and work area clean is vital to machine performance, we incorporate an upper and lower air-purge system to keep contaminants outside of the spindle.

| VMX24i | VMX24Di | VMX30i | VMX30Di | VMX42i | VMX42Di | VMX50i | |

| Travels: | 24 x 20 x 24 in | 24 x 20 x 24 in | 30 x 20 x 24 in | 30 x 20 x 24 in | 42 x 24 x 24 in | 42 x 24 x 24 in | 50 x 26 x 24 in |

| Table Size: | 30 x 20 in | 30 x 20 in | 40 x 20 in | 40 x 20 in | 50 x 24 in | 50 x 24 in | 59 x 26 in |

| Spindle(RPM): | 12,000 | 15,000 | 12,000 | 15,000 | 12,000 | 15,000 | 12,000 |

| Tools: | 30 CAT 40 | 30 CAT 40 / Big Plus | 30 CAT 40 | 30 CAT 40 / Big Plus | 30 CAT 40 | 30 CAT 40 / Big Plus | 30 CAT 40 |

| VMX50i-50T | VMX6030i | VMX6030i-50T | VMX64i | VMX64i-50T | VMX84i | VMX84i-50T | |

| Travels: | 50 x 26 x 24 in | 60 x 30 x 24 in | 60 x 30 x 24 in | 64 x 34 x 30 in | 64 x 34 x 30 in | 84 x 34 x 30 in | 84 x 34 x 30 in |

| Table Size: | 59 x 26 in | 66.14 x 30 in | 66 x 30 in | 66 x 35 in | 66 x 35 in | 86 x 34 in | 86 x 34 in |

| Spindle(RPM): | 8,000 | 12,000 | 8,000 | 12,000 | 8,000 | 12,000 | 8,000 |

| Tools: | 30 CAT 50 | 30 CAT 40 | 30 CAT 50 | 30 CAT 40 | 32 CAT 50 | 40 CAT 40 | 32 CAT 50 |

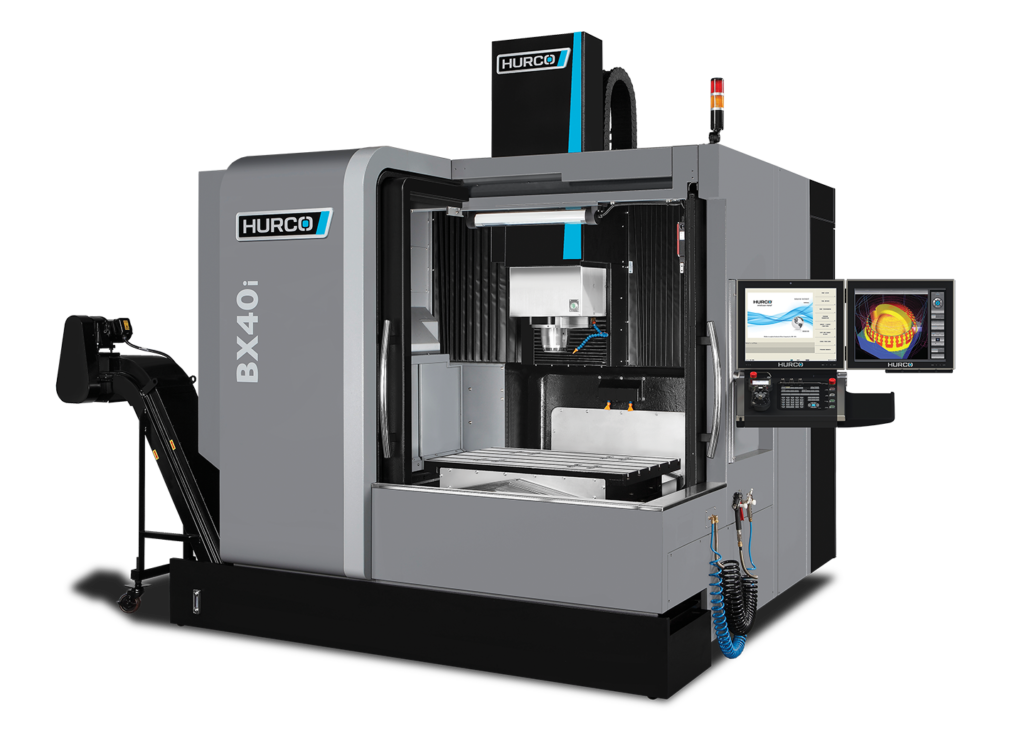

BX Series

High-Speed Double-Column Bridge Design CNC Machining Centers

The stability of the double-column, the ladder design of the Z-axis, and the overall weight of the BX high-speed milling machines provide exceptional accuracy, thermal compensation, and outstanding surface finish capabilities. Equipped with an 18,000 rpm HSK 64A spindle and Hurco’s patented UltiMotion technology, the BX series of CNC machines is designed for high speeds and tight tolerances.

Double-Column CNC Machines

- Extremely rigid and thermally stable double-column design.

- Ladder design of the bridge provides maximum support to the head casting.

- Close proximity of spindle to bridge casting reduces overhang.

- Roller-type rails on all axes provide additional rigidity.

- Direct-coupled ballscrews support increased speed and accuracy.

- Motorized high-speed spindle.

Premium Components Increase Performance

- Integral motorized spindle equipped with ABEC-7 ceramic hybrid bearings

- 30-station electric swing-arm ATC (50-station option available)

- Robust control specifications (standard) – 2.7GHz Dual-Core Processor

- 4GB RAM Memory, 128GB Solid State Hard Drive, 10,000 block lookahead

- Easy access to table

- Brushless AC Servos

- Solid cast iron frame

- Large front door opening / Large, hinged side doors

- Larger, heavy-duty roller ways on all three axes

- Yaskawa Sigma 5 drives

- LED lighting shines brighter and saves energy

- MAX5 ergonomically designed console with two 19” LCD screens

| BX40i | BX40Ui | BX50i | BX60i | |

| Travels: | 40.2 x 27.6 x 19.7 in | 37.4 x 23.6 x 19.7 in | 53.2 x 37.4 x 23.6 in | 63 x 51.2 x 27.6 in |

| Table Size: | 41.3 x 27.6 in | 13.7 in Dia. B Axis: -30°/+100° | 59.1 x 37.8 in | 74.8 x 51.2 in |

| Spindle(RPM): | 18,000 | 18,000 | 18,000 | 18,000 |

| Tools: | 30 HSK 63 | 30 HSK 63 | 30 HSK 63 | 30 HSK 63 |

DCX Series

Double-Column CNC Machining Centers

The DCX Series of Double Column CNC machining centers were created due to customer requests—customers who already knew the value of Hurco and needed larger machines for aerospace and energy parts. Our 2-meter, 3-meter, and 4-meter VMCs are the biggest machine tools available with the powerful Hurco control.

Double-Column Design Promotes Thermal Stability

When our customers requested a massive machining center that would accommodate the big parts and heavy cuts their aerospace and energy customers were ordering, we knew the design and mechanical engineering was critical.

After reviewing various configurations, the Hurco engineering team opted for a double column design because they determined it would provide superior dynamic behavior and promote thermal stability compared to other options. The large table capacity allows nearly any part you have to be machined.

Premium Components Increase Performance

We focus our efforts on reducing your overall cycle time while minimizing time wasted on non-cutting operations, by incorporating time-saving features in our DCX double column machining center design and using premium components.

The Heart of the Machining Center

The DCX CNC double column machining centers feature a powerful CAT50 cartridge spindle. The low base-speed of the spindle provides more torque for the machine without needing a gearbox, which eliminates additional assembly and maintenance.

Prolonging Spindle Life + Perserving Accuracy

Prolonging Spindle Life + Preserving Accuracy. We have systems in place to prolong spindle life and combat spindle growth caused by heat dissipation. We use (4) ABEC Class 7, 25-degree angular contact bearings in the DCX spindles. These bearings run at much lower temperatures, so they have a significantly longer lifespan and a much lower probability of failure. They are lubricated with an air/oil mist. Because keeping the spindle and work area clean is vital to machine performance, we incorporate an upper and lower air-purge system to keep contaminants outside of the spindle.

Best-In-Class Chip Management

High pressure, high volume, stainless steel coolant ring with adjustable nozzles delivers coolant right to the tool. Dedicated large capacity pump system and the dual auger that lifts up to a chip conveyor eliminate costly cleanup and save valuable time. Sloped telescopic way covers protect the internal components of the machining center.

Generous Tool Capacity ATC

Fully enclosed, side-mounted, swing-arm ATC gives you more room to work and has more tool capacity. The all-electronic design provides the reliability, speed, and near-zero maintenance you require.

| DCX22i | DCX22i-50T | DCX32i | DCX3226i | DCX42i | |

| Travels: | 86.6 x 66.9 x 29.5 in | 86.6 x 66.9 x 29.5 in | 126 x 82.7 x 36.2 in | 126 X 102 X 36.2 in | 165.4 x 102.4 x 43.3 in |

| Table Size: | 82.7 x 63 in | 82.6 x 63 in | 118.1 x 66.9 in | 118.1 X 82.7 in | 157.5 x 82.7 in |

| Spindle(RPM): | 12,000 | 6,000 | 6,000 | 6,000 | 80 hp / 60 kW @ 6,000 |

| Tools: | 40 CAT 40 | 40 CAT 50 | 40 CAT 50 | 40 CAT 50 | 40 CAT, BT, DIN 50 |

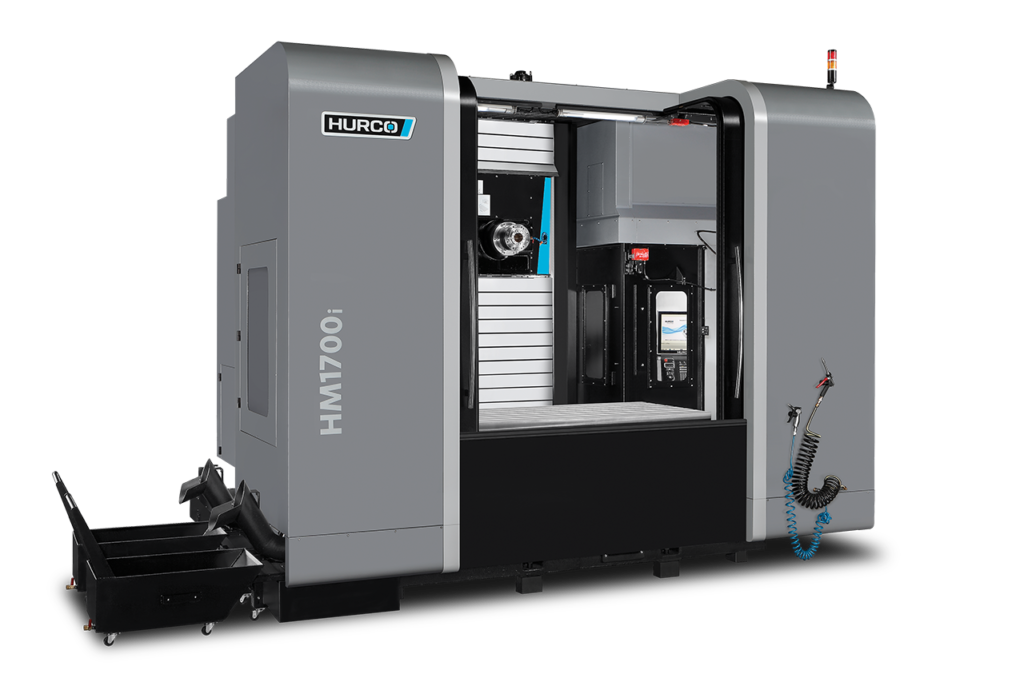

HM Series

Horizontal Mills Designed for Maximum Efficiency

These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations. The large, front and side access doors provide maximum operator efficiency. With fast rapids, large work cube, smart frame design, and UltiMotion technology, complex production parts can be CNC machined efficiently and accurately. Hurcos’ horizontal milling machines increase shop productivity with a rotary torque table, such as the table added to the smart design of the HM1700i CNC machining center.

Horizontal CNC Mills Designed for High-Mix Production

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- 800 mm torque table

- Linear roller guideways on XYZ axes

- Full B-Axis (360 degrees / 360,000 position)

- 8K rpm dual-wound spindle / 298 ft lbs of torque

- 10K spindle option available

- Practical design with large front and size doors for easy access

- Patented UltiMotion motion system included

- Direct drive B-axis table (torque table)

Premium Components Increase Performance

Finite Element Analysis (FEA) is used to evaluate structural rigidity, torsional stiffness, thermal characteristics, and natural frequency to achieve the best frame design. Critical with today’s high velocities and accelerations – machine performance must be carefully optimized in order to maintain part quality.

30 Station ATC: The 30 station ATC is side-mounted with a 3.7 second tool-to-tool ATC time. Hurco uses an electric tool changer with 4.7” max tool diameter and a 44 lb. max tool weight. The tool changer is random access.

Yaskawa Sigma V Digital Drives:

Hurco uses state-of-the-art premium servos and drives from Yaskawa, the world’s largest manufacturer of motors and drives. They provide enhanced vibration suppression and feature higher speed acceleration and deceleration.

- 625 millisecond velocity loop frequency response time (1.6 kHz)

- Encoders: 1,048,576 counts per revolution

| HM1700i | HM1700Ri | |

| Travels: | 67 x 51 x 35 in | 67 x 47 x 35 in |

| Table Size: | 67 x 36 in | Rotary Table 65 x 33 in |

| Spindle(RPM): | 8,000 | 8,000 |

| Tools: | 30 CAT 50 | 30 CAT 50 |

HBMX Series

Horizontal Boring Mills Efficiency Designed to have a Surprisingly Small Footprint and Large Work Envelope

The HBMX horizontal boring machines have 2-speed geared-head spindles, hardened box ways, and they are packaged to include features needed for typical applications—such as a programmable quill that allows you to use shorter tools, a contouring 4th axis rotary table (not just positional), linear glass scales to maintain thermal stability and increase accuracy, CTS, and a 60-tool ATC.

CNC Boring Mill Features

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- Box Ways for X,Y, Z Axes

- Geared, Liquid Cooled Spindle Design

- Direct Drive for X,Y, Z Axes

- Double-Nut Ballscrews

- Standard 2,500 RPM Spindle

- Yaskawa Sigma V Digital AC Servos

- Fast 393.7 ipm Rapid Traverse Rates X/Y/Z Axes, 157.5 ipm Rapid Traverse W Axis

- Electric Swing-arm 60 Station ATC – Random Access

- Metal Telescopic Way Covers

- Lift-Up Chip Conveyor

- Spindle Thermal Chiller

- Automatic Central Lubrication System

- Power Cabinet Heat Exchanger

- Flood Coolant

- Linear Scales

- Coolant Thru Spindle, 218 psi

- Full B-axis Rotary Table

- Oil Skimmer Assembly

- Modular One-Piece ITX Control Rack

- Rigid Tapping

- 2.7GHz Dual Core Processor

- 4 GB RAM Memory

- 128 GB Solid State Hard Drive

- 12 Months Parts and Labor Warranty (24 months Control and Drives)

Premium Components Increase Performance

We focus our efforts on reducing your overall cycle time while minimizing time wasted on non-cutting operations, by incorporating time-saving features in our horizontal milling machine design and using premium components.

Finite Element Analysis (FEA) is used to evaluate structural rigidity, torsional stiffness, thermal characteristics, and natural frequency to achieve the best frame design. Critical with today’s high velocities and accelerations – machine performance must be carefully optimized in order to maintain part quality.

Linear Glass Scales: The HBMXi boring mill machine line is equipped with linear glass scales as standard on XYZ axes. This helps reduce the effect of thermal instabilities. The linear glass scales help increase accuracy on all Hurco boring mills.

Double-nut Ballscrews: Hurco uses premium grade double-nut ballscrews that are anchored at both ends. The double-nut pretensioning presents pressure in opposite directions to the ballscrew. This keeps the nut under tension and prevents backlash and produces less thermal growth.

| HBMX55i | HBMX80i | HBMX120i | |

| Travels: | 55.1 x 54.7 x 43.3 x 19.7 in | 77.8 x 70.1 x 66.9 x 19.7 in | 118.1 x 70.1 66.9 x 19.7 in |

| Table Size: | 44.1 x 49.2 in | 56.7 x 63 in | 56.7 x 63 in |

| Spindle(RPM): | 2,500 (High) / 454 (Low) | 2,500 (High) / 454 (Low) | 2,500 (High) / 454 (Low) |

| Tools: | 60(90 opt) CAT 50 | 60(90 opt) CAT 50 | 60(90 opt) CAT 50 |

U Series

Trunnion Table 5-Axis Makes 5-Sided Machining Easy

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis CNC machine. The integrated trunnion table design provides more clearance in the Z-axis compared to other brands.

Benefits of Trunnion 5-Axis Mill

Easy transition from 3-axis machining. The 5-axis trunnion style machining centers are an ideal configuration for 5-sided machining, especially if you’ve always worked on a 3-axis machine because the trunnion style design uses the same principles as 3-axis (i.e., you still machine in a linear fashion, but you just machine more sides). This means less training, less setup time, and more flexibility.

More clearance in Z-axis. The integrated design of the trunnion table 5-axis milling machine gives you more clearance in Z, especially compared to 3-axis VMCs with a trunnion table added to simulate a 5-axis machining center.

Seamless integration. Seamless integration of pneumatic and/or hydraulic fixtures is another benefit. We purposely designed the U-Series 5-axis CNC mills so you can easily feed the cables for these types of fixtures through the casting.

Better undercut + larger work volume + more torque. Other reasons to choose the trunnion style configuration include better undercut capability because the trunnion rotates 110 degrees, it allows you to reach more complex geometry on the part, compared to machines that only tilt 90 degrees. Compared to a swivel head design, the trunnion style gives you a larger work volume because you don’t have to compensate for the space used by the swivel head with the tool attached.

Don’t Get Left Behind

According to benchmark data from Modern Machine Shop magazine, 44% of the highest performing shops in the U.S. use 5th axis positioning. Just as Hurco led the industry in the transition from manual machining to CNC machining with the invention of conversational programming, we have led the industry in the transition from 3-axis machining to 5-axis positioning (or 5-sided machining). At Hurco, customer productivity (which leads to customer profitability) is the primary criterion we use when deciding where to devote our research and development resources. Decades ago, the Hurco engineering team determined that 5-axis CNC machining, in particular, 5-sided machining, could significantly increase productivity at job shops. We set a path to become the experts and revolutionized the industry with the development of control technology that optimizes the process for full 5-axis and 5-sided (3+2).

With 5-sided CNC machining, also called 3+2, you reduce setup time, increase accuracy, and expand your shop’s capability for future simultaneous 5-axis work. The key to our success in helping machinists make the transition from 3-axis to 5-sided machining lies within the conversational programming features of the Hurco control, such as Transform Plane and 3D Import that creates Transform Planes automatically.

When you invest in a Hurco 5-axis machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center due to the powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

| VM10Ui | VM10UHSi | VMX30Ui | VMX30UHSi | VMX42Ui | VMX42UHSi | VMX60Ui | |

| Travels: | 21 x 16 x 19 in | 21 x 16 x 19 in | 30 x 20 x 20.5 in | 30 x 20 x 20.5 in | 42 x 24 x 20.5 in | 42 x 24 x 20.5 in | 60 x 26 x 20.5 in |

| Table Diameter: | 7.8 in | 7.8 in | 9.8 in | 9.8 in | 13.7 in | 13.7 in | 19.7 in |

| Spindle(RPM): | 12,000 | 20,000 | 12,000 | 18,000 | 12,000 | 18,000 | 12,000 |

| Tools: | 20 CAT 40 | 20 BT 30 | 40 CAT 40 | 40 HSK 63 | 40 CAT 40 | 40 HSK 63 | 40 CAT 40 |

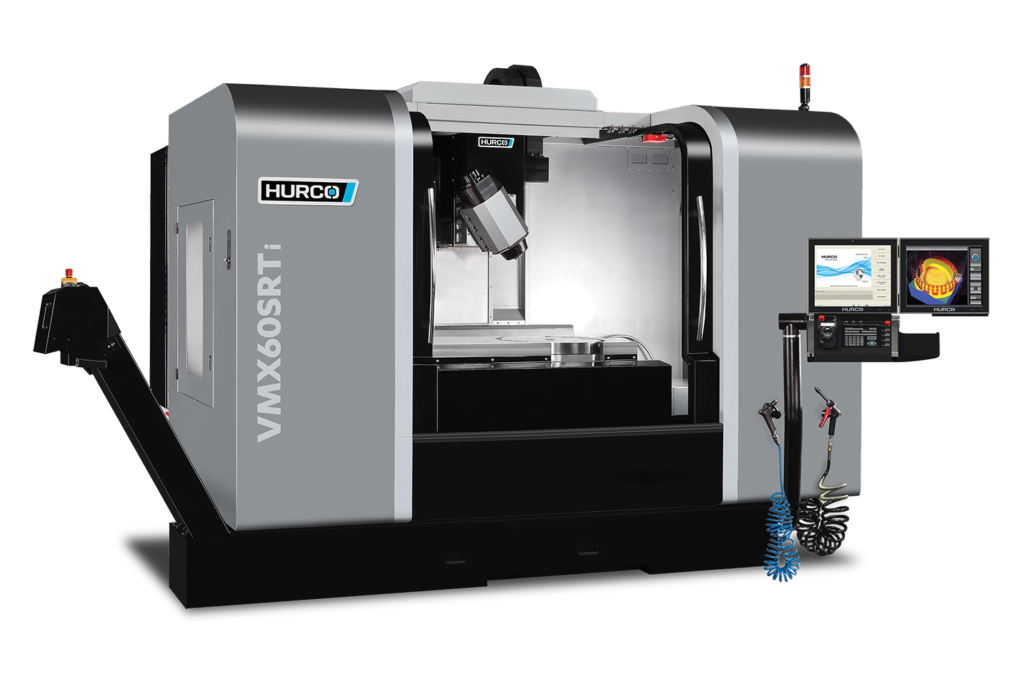

SRT/SW Series

5-Axis CNC Machining Center Offers Maximum Flexibility

The SRTi series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size the machine table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis CNC work. This configuration is also available in an SW model that utilizes the swivel head, traditional machine table, and an add-on A-axis rotary.

Benefits of the SRT 5-Axis CNC Machine

The design of the swivel head 5-axis machining center makes the SRT the best choice for certain applications.

Versatility. Since the rotary torque table is embedded within the generous machine table, you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is always flat and doesn’t tilt, the SRT 5-axis CNC machines swivel head and rotary table design are typically preferred to the trunnion style 5th axis machines when machining heavier parts. Because all of the weight is transferred down to the leveling pads and fully supported by the foundation of the machine.

Unlimited angular movement of the C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports the unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SRT 5 axis milling machines are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

We OWN 5-Axis + 5-Sided CNC Machining

At Hurco, we are immersed in 5-axis technology. We have carved out a niche in this arena because we made a commitment decades ago to dedicate our R&D resources to 5-axis and 5-sided. We determined this type of machining center, combined with the capabilities of our CNC control, would make our customers more profitable. Similar to the transition from manual mills to CNC mills, we know the transition from 3-axis to a 5-sided machining process is imperative for our customers to increase their profit margin on existing parts.

If you do NOT OWN a 5-axis machining center, the most important message you need to know: If you are machining features on multiple sides of the same part on a 3-axis mill, then you are already doing 5-sided machining…just manually. 5-sided machining on a 5-axis machine will reduce setup times, increase the profit margin of the parts you are producing on your 3-axis machining centers. The Hurco control makes programming easy for 5-sided—NO CAM needed!

Hurco machinist Mike Cope was so passionate about the need to educate shops about the transition to 5-sided machining and the capabilities of 5-axis machines, he wrote a book about it.

| VMX42HSRTi | VMX42SRTi | VMX60SRTi | VMX42SWi | VMX60SWi | VMX84SWi | |

| Travels: | 42 x 24 x 24 in | 42 x 24 x 24 in | 60 x 26 x 24 in | 42 x 24 x 24 in | 60 x 26 x 24 in | 84 x 34 x 30 in |

| Table Size: | 50 x 24 in | 50 x 24 in | 66 x 26 in | 50 x 24 in | 66 x 26 in | 86 x 34 in |

| Spindle(RPM): | 18,000 | 12,000 | 12,000 | 12,000 | 12,000 | 12,000 |

| Tools: | 40 HSK 63 | 40 CAT 40 | 40 CAT 40 | 40 CAT 40 | 40 CAT 40 | 40 CAT 40 |

VC/VCX Series

5-Axis CNC Mill with Cantilever Design Supports a Wide Range of Parts

The B-axis provides superb undercutting ability with a full 110° in both positive and negative directions. Solid one-piece cast iron frame optimized with both static and dynamic Finite Element Analysis (FEA).

The 5-Axis VC Series B-axis trunnion style configuration will allow for shorter tools to be utilized when cutting smaller parts. When cutting smaller parts on a traditional A-axis trunnion, the tools approach the part from behind the A-axis trunnion. This means when running smaller 5-Axis parts on larger machines, the operator is forced to use longer tools for clearance. Since a B-axis trunnion tilts around the Y-axis, the tool is always approaching the part from a safe direction and the possibility for interference is much less.

5-Axis CNC Machining – Cantilever

- Equipped with CTS and Linear Scales

- High-resolution encoders for increased precision.

- Larger heavy-duty roller ways on all three axes

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- 12,000 RPM In-line Spindle

- Yaskawa Sigma V Digital AC Servos

- 2.5 Second Tool-to-Tool ATC Time

- Double-Nut Ballscrews

- Yaskawa Sigma V Digital AC Servos

- 2.7GHz Dual Core Processor

- 4 GB RAM Memory

- 128 GB Solid State Hard Drive

Premium Components Increase 5-Axis Machining Center Performance

- Integrated trunnion table design provides more clearance in Z-axis and ability to machine heavier parts compared to 3-axis machining centers with trunnion table added

- +110° / -110° B-axis motion delivers better undercut capability

- Larger, heavy-duty roller ways on all three axes

- Solid one-piece cast iron frame optimized with both static and dynamic Finite Element Analysis (FEA)

- Yaskawa Sigma V Digital AC Servos

- 5 axis/ 5-sided machining software features Tool Path Linearization, Tool Center Point Management, Transform Plane, 3D Tool Compensation, Tool Vector Input & Retract, Shortest Angular Traverse, 3D Import

- 2 or 4 passage rotary unions for hydraulics and/or air

- Electric, side-mounted, 30-Station swing-arm ATC

- Full Enclosure with wide front access doors and fully contained tool storage

- Angular encoders for rotary axes

- Pistol-style coolant and air guns

- Z-axis regenerative brake – no counterbalance

| VC500i | VCX600i | |

| Travels: | 20.5 x 17.7 x 15.8 in | 24 x 20.5 x 19 in |

| B Axis: | -110°/+110° | +110°/-110° |

| Table Diameter: | 19.7 in | 23.6 in |

| Spindle(RPM): | 12,000 | 12,000 |

| Tools: | 30 CAT 40 | 40 CAT 40 |

TM Series

CNC Lathe for General Purpose Turning

The small footprint, large work cube, chip management system, and an affordable price tag of our slant-bed CNC turning centers make small-batch manufacturing profitable.

The TM Series CNC turning centers are designed for general purpose turning applications and provide an easy transition from manual turning or milling.

Design + Construction: We use thick-walled, fine-grain cast iron for the major structural assemblies (base, headstock, and cross slide). The rigid one-piece machine base casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting. The box type cross slide ensures the turret remains rigid and stable even during the most rigorous cycles. We also use large linear guideways that are strategically spaced to provide excellent support to the cross slide. Hydraulic Turret: The slotted tool turret is designed to provide fast and accurate tool indexes. You can use any combination of ID and OD tool holders. The turret uses a large cervic coupling for accurate location and clamping. Machining Capacity: The generous turning diameter and turning length allow a wide range of part sizes and applications.

Features

Our control technology is the greatest advantage of our lathes because the technology we develop yields the greatest opportunity for our customers to increase profitability via increased productivity. With large capacity memory, a fast processor, and multiple control features that minimize setup time, you will benefit from a control that helps you get from print to part faster.

Premium Components + Expert Design

Spindle Motor and Drive: The spindles on the Hurco TM Series of slant-bed CNC lathes utilize poly-V belts, which are ideal for turning. The spindle speed ranges have been engineered for the best metal removal rate for a given chuck size, up to 6,000 rpm. We use precision steel bearings packed with lifetime grease, which results in maintenance-free lubrication. The brushless, AC motor drives the spindle and delivers impressive power and torque.

Guideways: The guide mechanism for the axes is fitted with precision linear ball rails. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote a long life.

Ball Screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter X-axis and Z-axis double nut ball screws are hardened and ground, centered between the guideways, and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

| TM6i | HTL8-60i | TM8i | TM10i | TM12i | |

| Travels: | 7x, 14z in | 12x, 63.5z in | 8x, 20z in | 9.8x, 29.5z in | 12x, 40z in |

| Max. Turning Dia.: | 12.4 in | 14 in | 17.7 in | 21.7 in | |

| Max. Turning Length: | 13.4 in | 59.1 in | 17.6 in | 28.4 in | 39.4 in |

| Max. Bar Capacity: | 1.75 in | 1.25 in | 2 in | 3 in | 4 in |

| Spindle: | 6,000 | 2,600 | 4,800 | 3,000 | 2,800 |

TMM Series

General Purpose Mill Turn CNC Lathes

The TMM turning centers are true slant-bed lathes equipped with live tooling and a programmable C-axis. The TMM live tooling lathes are the perfect way to make small to medium lot sizes that require turning and secondary milling/drilling operations profitable. Save time with one setup and you won’t lose accuracy due to refixturing.

Live Tool CNC Lathes

The most significant advantage of the Hurco TMM CNC lathes with live tooling is the simplified programming on the CNC control. Learn more about mill-turn control features. Beyond the control technology, the TMM lathes with live tooling have multiple design features that prove valuable for mill-turn applications in today’s machine shop.

Design + Construction: We use thick-walled, fine-grain cast iron for the major structural assemblies (base, headstock, and cross slide). The rigid one-piece machine base casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting. The box type cross slide ensures the turret remains rigid and stable even during the most rigorous cycles. We also use extra wide linear guideways that are strategically spaced to provide excellent support to the cross slide.

Fast, Servo Turret: The slotted tool turret is designed to provide fast and accurate tool indexes. You can use any combination of ID and OD tool holders in the tool stations. The turret uses a large service coupling for accurate location and clamping.

C-Axis: The C-Axis programs to .001 degree and it is standard on the Hurco lathes with live tooling—not an additional charge like competitor models.

Premium Components + Expert Design

All Hurco, mill-turn CNC lathes are built for increased rigidity with an extra-wide saddle and larger Z-axis rails. You can be assured Hurco mill-turn CNC lathes have the premium components and rigidity required.

- One-piece bed casting for maximum rigidity.

- Ergonomic design features make each process more efficient.

- Convenient front access to chuck and tailstock pressure controls.

- Front-loading coolant tank and chip conveyor design to minimize maintenance and provide easy access.

- The 30-degree true slant bed design promotes larger turning capacity in addition to efficient chip removal.

- Component isolation system minimizes heat dissipation and protects the spindle head to combat spindle growth.

- Chip management features protect internal components

- Telescopic way covers

- Inside door track

- Washdown and air guns

- Adjustable brass coolant nozzles

- Premium Components

- The VDI servo turret provides quick-change tooling and fast indexing, features large, curvic coupling for superior rigidity, and makes all stations live-tool capable.

- The short, live-tool drive train generates less heat and provides more horsepower and torque transfer to the tool, higher reliability, and quieter operation.

- Advanced spindle technology with high output spindle motor. Additionally, the spindle motor is strategically designed for easy access and easy maintenance.

- Guideways: The guide mechanism for the axes is fitted with precision linear ball rails. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote a long life.

- Ball screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned, double-nut ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter double-nut ball screws are hardened and ground, centered between the guideways and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

- Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

| TMM8i | TMM10i | TMM12i | |

| Travels: | 7.8x, 20z in | 9.8x, 29.5z in | 12x, 40z in |

| Max. Turning Dia.: | 10.1 in | 11.6 in | 14.2 in |

| Max. Turning Length: | 17.9 in | 27.6 in | 36.9 in |

| Max. Bar Capacity: | 2.04 in | 3.07 in | 4.09 in |

| Spindle: | 4,000 | 3,000 | 2,800 |

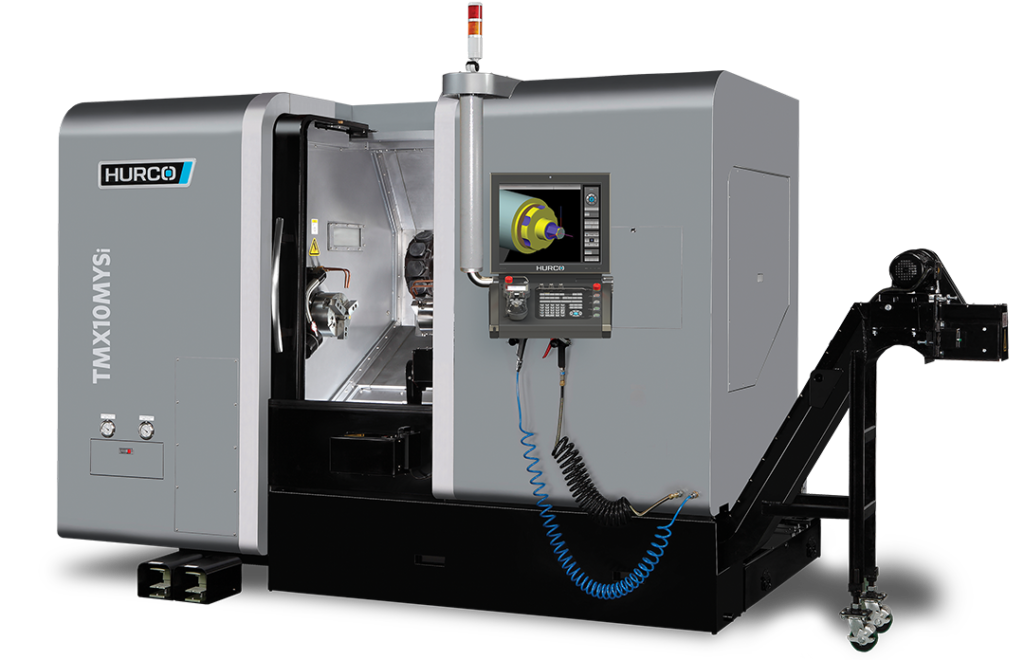

TMX Series

CNC Lathes for Performance Turning

The TMX series of CNC Lathes are a true slant-bed lathe with all-digital drives and motors with absolute encoders on all linear axes. With increased travels, more horsepower and torque, increased rigidity, faster rapids, faster acceleration/deceleration rates, and a programmable tailstock, the TMX CNC turning centers are built for rigorous cycles.

The TMX slant-bed CNC lathes are ideal for medium-sized batches and larger. They have many of the design specifications required for high performance turning.

Design + Construction: It starts with a certified Meehanite® casting, which provides superb dampening characteristics that inhibit thermal deformation and twisting. This robust machine tool features oversized Z-axis guide rails that are strategically spaced to provide excellent support to the cross slide. A wide saddle increases rigidity even further. Ultimately, all of these design features mean the TMX lathes can withstand heavier loads and more momentum.

Servo Turret: Fast Duplomatic servo turret with 12-tool stations is designed to provide faster and more accurate tool indexes. You can use any combination of ID and OD tool holders.

Heat Isolation System: Because heat is the enemy of machine tools, we’ve designed our TMX lathes to promote thermal stability by isolating heat producing components and adding a spindle chiller.

Machining Capacity: The generous turning diameter and turning length allows a wide range of part sizes and applications.

CNC Lathe Control Features

Our control technology is the greatest advantage of our lathes because the technology we develop yields the greatest opportunity for our customers to increase profitability via increased productivity. With large capacity memory, a fast processor, and multiple control features that minimize setup time, you will benefit from a control that helps you get from print to part faster.

Premium Components + Expert Design

- Spindle Motor and Drive: The spindles on the Hurco TMX Series of slant-bed CNC lathes utilize poly-V belts, which are ideal for turning. The spindle speed ranges have been engineered for the best metal removal rate for a given chuck size, up to 6,000 rpm. We use precision steel bearings packed with lifetime grease, which results in a maintenance-free lubrication. The brushless, AC motor drives the spindle and delivers impressive power and torque.

- Guide ways: The guide mechanism for the axes is fitted with precision linear ball rails. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote long life.

- Ball Screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter X-axis and Z-axis double nut ball screws are hardened and ground, centered between the guide ways, and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

- Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

| TMX8i | TMX10i | |

| Travels: | 8.7x, 22z, 25.2w in | 9.2x, 26z, 29.1w in |

| Max. Turning Dia.: | 14 in | 16.3 in |

| Max. Turning Length: | 21.1 in | 25 in |

| Max. Bar Capacity: | 2.5 in | 3 in |

| Spindle: | 4,500 | 3,500 |

TMX MY & MYS Series

Multi-Axis Mill-Turn CNC Machining Made Easy

The TMXMY/S mill turn CNC lathes are true slant-bed lathes with all-digital drives and motors and absolute encoders on all linear axes. The addition of the Y-axis allows you to machine a pocket with straight walls and flat bottoms or perform off-center machining operations with just a click of a box.

The most significant advantage of the multi-axis TMXMY/TMXMYS dual spindle CNC lathes is the simplified programming and operation via the CNC control. By simply checking a box, the control activates linear Y-axis motion. The sub-spindle functions are similarly straightforward. Learn more about mill-turn control features. Beyond the control technology, the TMXMY and TMXMYS CNC turning centers have multiple design features that prove valuable for mill-turn applications.

- Design + Construction: It starts with a certified Meehanite® casting, which provides superb dampening characteristics that inhibit thermal deformation and twisting. This robust machine tool features oversized guide rails that are strategically spaced to provide excellent support to the cross slide. A wide saddle increases rigidity even further. Ultimately, all of these design features mean the TMXMY/MYS sub-spindle CNC lathes can withstand heavier loads and more momentum.

- Servo Turret: Fast Duplomatic servo turret with 12- driven tool stations is designed to provide faster and more accurate tool indexes. You can use any combination of ID and OD tool holders.

- Heat Isolation System: Because heat is the enemy of machine tools, we’ve designed our TMXMY/MYS twin spindle lathes to promote thermal stability by isolating heat-producing components and adding a spindle chiller.

- Machining Capacity: The generous turning diameter and turning length allow a wide range of part sizes and applications.

Premium Components + Expert Design

All Hurco, mill-turn CNC machines are built for increased rigidity with an extra-wide saddle and larger Z-axis rails. You can be assured our TMXMY and TMXMYS multi-spindle lathes have the premium components and rigidity required.

- One-piece bed casting for maximum rigidity.

- Ergonomic design features make each process more efficient.

- Convenient front access to chuck and tailstock pressure controls.

- Front-loading coolant tank and chip conveyor design to minimize maintenance and provide easy access.

- The 30-degree true slant bed design promotes larger turning capacity in addition to efficient chip removal.

- Component isolation system minimizes heat dissipation and protects the spindle head to combat spindle growth.

- Chip management features protect internal components

- Telescopic way covers

- Inside door track

- Washdown and air guns

- Adjustable brass coolant nozzles

- Premium Components

- The VDI servo turret provides quick-change tooling and fast indexing, features large, curvic coupling for superior rigidity, and makes all stations live-tool capable.

- The short, live-tool drive train generates less heat and provides more horsepower and torque transfer to the tool, higher reliability, and quieter operation.

- Advanced spindle technology with high output spindle motor. Additionally, the spindle motor is strategically designed for easy access and easy maintenance.

- Guideways: The guide mechanism for the axes is fitted with precision linear ball rails. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite

- Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote long life.

- Ball screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned, double-nut ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter double-nut ball screws are hardened and ground, centered between the guideways and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

- Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

| TMX8MYi | TMX8MYSi | TMX10MYi | TMX10MYSi | |

| Travels: | 8x, 22z, 4.4y, 25.2w in | 11.4x, 22z, 4.4y, 25.2w in | 8.8x, 26.4z, 4.4y, 29.1w in | 8.76x, 26.38z, 4.4y, 29.1w in |

| Max. Turning Dia.: | 10.9 in | 13.2 in | 14.8 in | 14.8 in |

| Max. Turning Length: | 20.7 in | 20.8 in | 24.7 in | 24.7 in |

| Max. Bar Capacity: | 2.5 in | 2.5 in | 3 in | 3.07 in |

| Spindle: | 4,500 | 4,500 | 3,500 | 3,500 |

| Features: | Y-Axis, Live Tool | Y-Axis, Live Tool, Sub-Spindle | Y-Axis, Live Tool | Y-Axis, Live Tool, Sub-Spindle |

TM Series (Heavy Duty)

Large CNC Lathes for Heavy Duty Cycles

Our heavy-duty slant-bed CNC lathes are a prime example of customer-centric design. Hurco customers who are suppliers for the aerospace and energy sectors requested larger CNC lathes with high torque capabilities and equipped with the Hurco CNC control.

Rigidity is absolutely critical for CNC turning heavy parts—that’s why we evaluate each design decision to ensure it promotes rigidity, reliability, and longevity.

Design + Construction: It starts with a certified Meehanite® casting, which provides superb dampening characteristics that inhibit thermal deformation and twisting. This robust machine tool features oversized Z-axis guide rails that are strategically spaced to provide excellent support to the cross slide. A wide saddle increases rigidity even further. Ultimately, all of these design features mean the Hurco heavy duty CNC lathes can withstand heavier loads.

Maximum Torque The TM heavy duty CNC turning centers are equipped with a two-speed gearbox that gives you the ability to achieve maximum torque at low speeds and maintain adequate torque at high speeds.

Servo Tool Turret: Fast turret with 12-tool stations is designed to provide faster and more accurate tool indexes. You can use any combination of ID and OD tool holders.

Heat Isolation System: Since heat is the enemy of machine tools, we’ve isolated heat-producing components and added a spindle chiller to promote thermal stability and minimize heat dissipation.

Machining Capacity: The generous turning diameter and turning length allow a wide range of large and long part sizes.

Premium Components + Expert Design

Spindle designed for maximum torque: The spindle features a cartridge design packed with lifetime grease, which provides maintenance-free lubrication. To maximize torque, the spindle is equipped with a gearbox that switches gears automatically to provide the best torque available at a given speed.

Guideways: The guide mechanism for the axes is fitted with precision linear ball rails and box ways for the tailstock. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote a long life.

Ball Screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter X-axis and Z-axis double nut ball screws are hardened and ground, centered between the guideways and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

| TM18i | TM18Li | TM18LBBi | |

| Travels: | 17x, 40z in | 17x, 80z in | 17x, 75.8z in |

| Max. Turning Dia.: | 25 in | 25 in | 25 in |

| Max. Turning Length: | 39.4 in | 79.4 in | 75 in |

| Max. Bar Capacity: | 6.4 in | 6.4 in | 10.8 in |

| Spindle: | 1,600(High) 600(Low) | 1,600(High) 600(Low) | 650(High) 400(Low) |

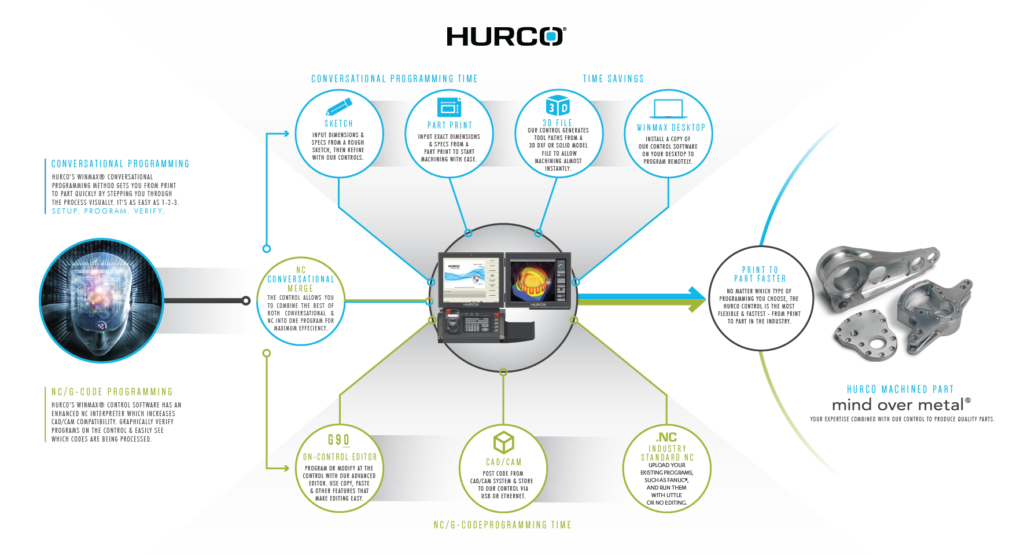

WinMax Control

The Hurco CNC Control Increases Customer Profitability

Nobody gets you from print to part faster than Hurco

The integrated Hurco CNC control and conversational programming powered by WinMax® is the most versatile and intuitive out of any of the CNC controls in the industry. More importantly, each feature has benefits that you can measure in terms of increased productivity, which leads to increased profitability.

WinMax Software = Conversational Programming +NC Programming

Just like you, Hurco engineers are focused on continual improvement—they are driven to develop CNC control technology that will make your business more profitable.

All of our new i-series machines have WinMax with lots of new features and UltiMotion.

Automation

ProCobots

Hurco has partnered with ProCobots to help our customers with their Job Shop Automation needs. In our annual survey, customers say finding operators is the number one problem they face. The idea surrounding Practical Job Shop Automation by ProCobots is the idea that the right system will free up machinists to do more of the high-value tasks while the automation equipment handles the redundant machine tending tasks. Focused on high mix/low volume production, ProCobots offers automation systems that can be connected to any new or existing machine tool. No experience with robotics is required.