[product-catalogue id=’3406′]

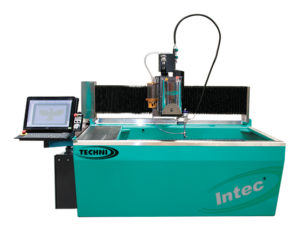

Intec-G2® Value Series

Intec-G2® Value Series

The Intec-G2® Value Series of Water Jet Cutting Systems represents the greatest “VALUE” for money available in the world of profile abrasive Waterjet cutting. The Intec-G2® water jet machine can cut almost any material to 8″ (200 mm) thick at maximum cutting speeds with minimum Capital outlay. The Intec-G2® is based on the same design platform as the Techjet-X3®. It is these same design solutions that will provide each Intec-G2® customer with a Water jet cutting machine that lasts longer and requires less maintenance, while delivering an easy to use, fast and accurate system at a very competitive price.

Sizes Range: 3′ x 5′ to 10′ x 20′

Techjet-X3® Performance Series

Techjet-X3® Performance Series

he Techjet-X3® series is the latest in our evolution of innovative products to create a precision, easy-to-operate, safe and highly reliable Waterjet Cutting Machine. The Techjet-X3® is built to the highest tolerances and incorporates Linear Scale Feedback to ensure the highest accuracy of motion in the industry. By mapping the entire cutting area with a laser interferometer, the motion system can deliver positional accuracy of 0.0005” (0.01mm) and high cutting speeds of up to 1000ipm or 25m/min.

measureThe Techjet-X3® is designed and built to the highest quality standards of Profile Waterjet Cutting Machine manufacture, incorporating practical design features and high quality components. It was these practical Design Solutions that won it the prestigious “Excellence in Product Design” Award at the Manufacturing Innovation Excellence Awards upon its introduction into the market in 2001.

It is these same design solutions that will provide each Techjet-X3® customer with a Waterjet machine that lasts longer and requires less maintenance, while delivering an easy to use, fast and extremely accurate system at a competitive price.

Size Ranges: 3′ x 5′ to 10′ x 20′

PAC 60TM Bevel Cutting Head

PAC 60TM Bevel Cutting Head

The PAC 60TM is capable of producing parts with a true angle up to +/- 60 degrees with continuous rotation. That means that regardless of the geometry of the part to be cut, the PAC 60TM will produce it without having to reposition the cutting head, saving time and producing higher quality parts.

Constant Stand Off – Bevel Cutting

The PAC 60™ incorporates as standard “Touch Probe” height detection to set a precise stand-off before piercing, or to predetermine the flatness of the material and make compensations in the “Z” height, to maintain an accurate stand-off while bevel cutting. An optional Laser Sensor is also available to perform Precision Terrain Mapping on the surface of the material to be cut. This information is then used to maintain an accurate stand-off distance between the nozzle and the work piece, resulting in more accurate parts than any other 5 axis head on the market. Other 5 axis heads set their stand-off only at the piercing point and then assume the work piece is completely flat along the cut path, which is almost never the case. As material flatness varies and stand-off changes, so does the geometry of the part being cut. So a constant, accurate stand-off is critical when angle cutting, and the greater the angle, the more critical it becomes.

Reduced Taper

The PAC 60™ operating software incorporates the True Cut® algorithms data base, developed to determine the predicted taper at a given surface finish. This taper is then compensated for when cutting the part, anywhere from 0 to 60 degrees, giving you “Precision Angle Control” of any part that can be produced on an X-Y abrasive waterjet cutting machine.

Direct Drive Technology

By incorporating patented† Direct Drive DC Servo Motor Technology for the 4th & 5th axis, the PAC 60™ is capable of positioning accuracy to ± 0.1 degrees with rapid acceleration and positioning speeds. Making the PAC 60™ the fastest, most accurate 5 axis waterjet cutting head available in abrasive waterjet cutting.

Tech-Sense™ Capability

The PAC 60™ is also available with the patented “Tech-Sense™” to ensure your bevel cutting head is working efficiently. When Tech-Sense™ is used in conjunction with Softec® Mobile Phone Communication, you can receive and reply to text messages from wherever you want. This unique feature makes “Lights Out” operation a reality, something very useful on a Water jet machine where run times can be hours or days.

Water Jet Pump – The Future in Waterjet Cutting Technology

Water Jet Pump – The Future in Waterjet Cutting Technology

The TECHNI Waterjet™ Quantum NXT™ water jet pump is a revolutionary concept in waterjet cutting. It incorporates a servo motor directly enveloping a high load, precision ball screw. The ball screw directly houses the ceramic plungers, which reciprocate back and forth to create the pumping action, in much the same way as a hydraulic cylinder works on an intensifier waterjet pump. The infinite control of the servo motor and precision of the ball screw, enable extremely accurate control over the output pressure and volume of the water displaced, and eliminates pressure spikes when deadheading. This infinite control gives an operator the ability to program virtually any pressure and flow rate from zero to full capacity, while only using the power displaced at the cutting head.

The TECHNI Waterjet™ Quantum NXT™ is by far the most efficient waterjet pump available on the market, delivering “real” efficiency gains and “real” savings.

The Quantum NXT™ only ever uses the power required for the cutting process. This means that regardless of whether the cutting head is open or closed, or the pressure or flow is reduced, there are no additional power losses.

- Most Efficient Waterjet Pump – up to 60% more efficient than standard hydraulic intensifiers

- Lowest Cooling Water Requirement – up to 75% less cooling water than standard hydraulic intensifiers

- Most Quiet – <68dBA with almost silent operation

- Smallest Footprint – over 50% less sq. ft. than an average hydraulic intensifier and lower profile and more ergonomic

- Longest Life Fittings and Tubing – due to the elimination of “dead head” pressure spikes

- Easiest Maintenance – easy access and improved visual diagnostics

- Superior Design – quick-change seal components for the fastest seal change in the industry

- Smartest – Intelligent Diagnostic Control reduces maintenance and increases uptime

- Environmentally Friendly – significantly less consumption of water & power, and minimal oil usage compared to standard hydraulic intensifiers

Servo Actuator

Servo Actuator

Servo Actuator to Replace Hydraulic Ram in Plunger Pumps

The Quantum Electric Servo Pump (ESP) incorporates core “direct servo” technology to replace hydraulic cylinders with highly compact, efficient, reliable, quiet and infinitely controllable Servo Actuators. The ESP actuator has been designed so that it can be easily adapted to other pumping applications. The Servo Actuator can be simply adapted to any existing plunger pump, to turn a Hydraulic driven plunger pump into an Electric Servo Pump.

Suitable for almost any pumping application where precision control is required

OEM’s can purchase the core components to effectively develop their own Electric Servo Pumps. This will allow OEM’s to have their own branded product, set up in a configuration that best suits their target market. TECHNI can assist with the engineering, including customising of the control algorithm to create the ultimate pressure curve for the application.

Core Components

- ESP Control Module, Yaskawa Drive and Software

- Motor Housing and mechanical drive assembly.

- Lubrication and internal cooling circuit.

Optional Components

- HP Components, including; Ceramic Plungers, Attenuator, HP Cylinders, Sealing Heads, Safety Dump Valves, Guide Bush assemblies, HP Seals etc.

- Switch gear, pressure transducer, and HMI.

- Advanced Diagnostic Kit.

- Frame & guards (can be customised)

Waterjet Cutting Software

Waterjet Cutting Software

Softec™ Waterjet Cutting Software has been developed by TECHNI Waterjet with two very clear goals in mind;

- To cut parts at the minimum cost with the greatest accuracy, and

- To have a simple and intuitive interface with the operator.

At the “Heart” of Softec™ is Tru-Cut Technology™, a highly sophisticated algorithms database that determines the optimum cutting speeds and machine ramping characteristics. Once you select the material to be cut, its thickness and surface edge finish required, the computer will take care of the rest, ensuring the minium cutting time for any given part. (Note: you can also add new materials if required)

Softec waterjet cutting software includes the following features:

- DXF Importation

- Standard Objects Library

- Re-Start Cutting from Anywhere

- Auto and Array Nesting

- Five edge qualities, selectable for each line

- Costing and estimating package

- Simple to use C.A.D. package

- Scanned Image ‘Clean Up’ function

- Trouble shooting Diagnostics

- Dynamic Wear Compensation

- Multiple Piercing Options

- Virtual Plate Orientation

- Real Time Running and Simulation

- Multiple origin points

- Design Mode

- Dry Run Mode

- Maintenance Timers

- Off Site Notification

Tru-Cut Technology

Tru-Cut waterjet cutting software technology

Advanced abrasive water-jet cutting technology

- Abrasive water-jet cutting technology has revolutionised the way many industries efficiently cut a wide range of materials. But not all abrasive water-jet cutting equipment is the same. Above all other considerations, it is the quality of the software driving the abrasive water-jet cutting equipment that determines its overall performance efficiency and value for money.

- Users demand abrasive water-jet cutting equipment that works at the optimum speed while producing accurate and high quality cuts, with minimum striations and other defects. And to satisfy modern demands for higher productivity, the equipment must be low maintenance and simple to operate – a big ask for what is a complex and multi-faceted process. While many claim to manufacture advanced abrasive water-jet cutting equipment, very few can achieve in practice the competitive advantage, performance and reliability of Tru-Cut® technology.

Waterjet Cutting Software that puts the operator at the cutting edge

- Modern abrasive water-jet cutting technology is a child of the computer age and Tru-Cut® technology is true to type. The heart of its functionality lies in advanced software that has been developed, tested and refined over many years by TECHNI Waterjet.

- Minor variations in material thickness, cutting pressure, type and amount of abrasive, part geometry and the tightness of radii in corners requires continuous re-calibrations and adjustments to yield the most efficient cutting times and quality results. The proprietary algorithms in Tru-Cut® software deal reliably and effortlessly with these ever changing variables in real time. Cutting speeds are dynamically optimised to compensate for all types of otherwise problematic and potentially wasteful situations.

Advanced Nesting Software (Option)

Softec Nest™ utilizes advance nesting algorithms which have been developed by one of the world’s largest and most awarded CAD and nesting software developers – Geometric Global

Benefits

- Waterjet Cutting SoftwareNest main pic copy

- Increasing Material Yield (More Parts Per Sheet)

- Minimizing Rapid Feed Times (More Sheets Per Hour)

- Increasing Nesting Speed (Reduced Programming Time)

- Increasing Remnant Size (Less Material Per Part)