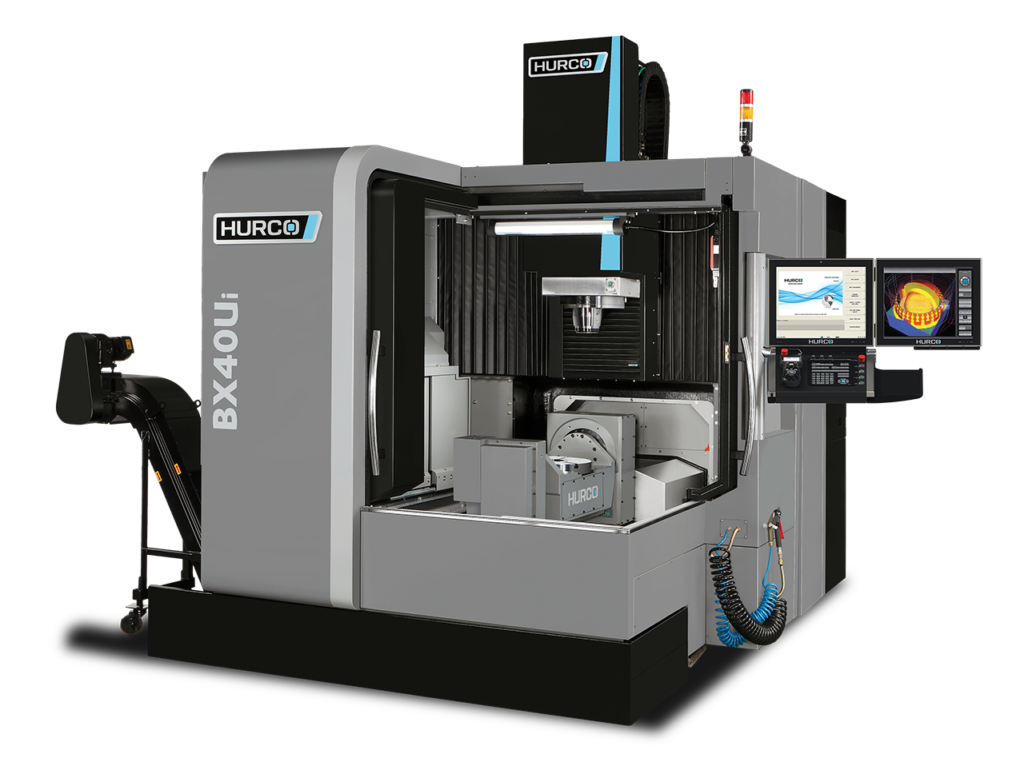

Hurco BX40Ui

Vertical Machining Center – 5-Axis High-Speed Double-Column Bridge Design

Double-Column Machining Center, BX Series

The Hurco BX40Ui CNC double-column machine center, with trunnion table mounted along the Y-axis, is the perfect combination of performance and flexibility. The ladder structure and double-column design provides extreme rigidity and outstanding support for the head. With an 18k motorized spindle and oversized linear guide rollers, the BX40Ui is perfect for a wide range of applications. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Main Specs:

- Travel: 37.4″ x 21.6″ x 19.7″

- Table Diameter: 13.7″

- Spindle: 18,000 RPM, 88 ft/lbs @ 2,800

- Tool Capacity: 30 HSK63

- Machine Weight: 20,062 lbs

Hurco’s Control Gets You from Print to Part Faster

The Only Dual-Screen Control Console in the Industry

Hurco is the only CNC machining center that gives you the added benefit of a dual-screen control. You can get the job done with a single screen, but the dual-screen makes everything faster and easier.

Data Block Search helps you edit a part program to correct a feature. Instead of searching through lines of code, you simply use the graphics screen to select the part feature you need to edit, and the corresponding line of code appears on the other screen so you can quickly make the change.

Concurrent Programming is another feature that is enhanced with the dual-screen control. While the machining center is running one part, you can program the next part without interrupting the cycle.

DXF Transfer allows you to simply import the CAD image, select the desired features, and the WinMax control automatically creates the program. Then check the part program on the screen with our powerful verifications graphics system that includes 3D solid rendering of the tool path with dynamic rotation and real time tool display. You can view the part from any angle without being forced to redraw it.

Features

The stability of the double-column, the ladder design of the Z-axis, and the overall weight of the machine (over 20,000 lbs.) provide exceptional accuracy and outstanding surface finish capabilities. Equipped with an 18,000 rpm spindle and Hurco’s patented UltiMotion technology, the BX40i is designed for high speeds and tight tolerances.

Standard

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- Oversized linear guide rollers

- Ladder structure which provides outstanding support for head

- Double-Nut Pre-Tensioned Ballscrews Anchored at Both Ends

- High Speed 18,000 RPM Motorized Spindle

- Fast 1,535 ipm Rapid Traverse Rates all axes

- Electric Swing-arm 30 Station ATC – Random Access

- LED Work Light

- Door Safety Interlocks / ANSI B11.23

- Flood Coolant Ring and Washdown System

- Pistol-style Coolant and Air Guns

- Metal Telescopic Way Covers

- Lift-up Belt Style Chip Conveyor

- Linear Scales

- Oil Skimmer

- Spindle Thermal Chiller Assembly

- Automatic Central Lubrication System

- Air Blow Feature

- Power Cabinet Heat Exchanger

- Modular One-Piece ITX Control Rack

- 2.7GHz Dual Core Processor

- 4GB RAM Memory

- 128GB Solid State Hard Drive

- 12 Months Parts and Labor Warranty (24 months Control and Drives)

Hurco BX40Ui Machine Specifications

| Travel | |

| X-Axis | 37.4″ |

| Y-Axis | 21.6″ |

| Z-Axis | 19.7″ |

| Spindle Nose to Table | 3.5″ – 25.7″ |

| Table | |

| Dimensions | 13.7″ Diameter |

| Max Load | 551 lbs |

| B-Axis Motion | -30º/+110º |

| C-Axis Motion | 360º |

| Spindle | |

| Spindle Type | Direct Drive |

| Spindle Speed | 18,000 RPM |

| Spindle Torque | 88 ft/lbs |

| Spindle Motor | 47 HP |

| Coolant Thru Spindle | Optional |

| Spindle Taper | HSK63A |

| Feed Rate | |

| Rapid Traverse (X/Y/Z) | 1,535/1,535/1,535 ipm |

| ATC | |

| Capacity | 30 Tools |

| Max. Tool Diameter | 3.0″ |

| Max. Tool Length | 11.8″ |

| Requirements | |

| Air Pressure | 5 CFM @ 80-100 psi |

| Power Consumption | 52 KVA |

| Machine Net Weight | 20,062 lbs |

| Operating Dimensions | 190.7″ x 146.6″ x 124.7″ |