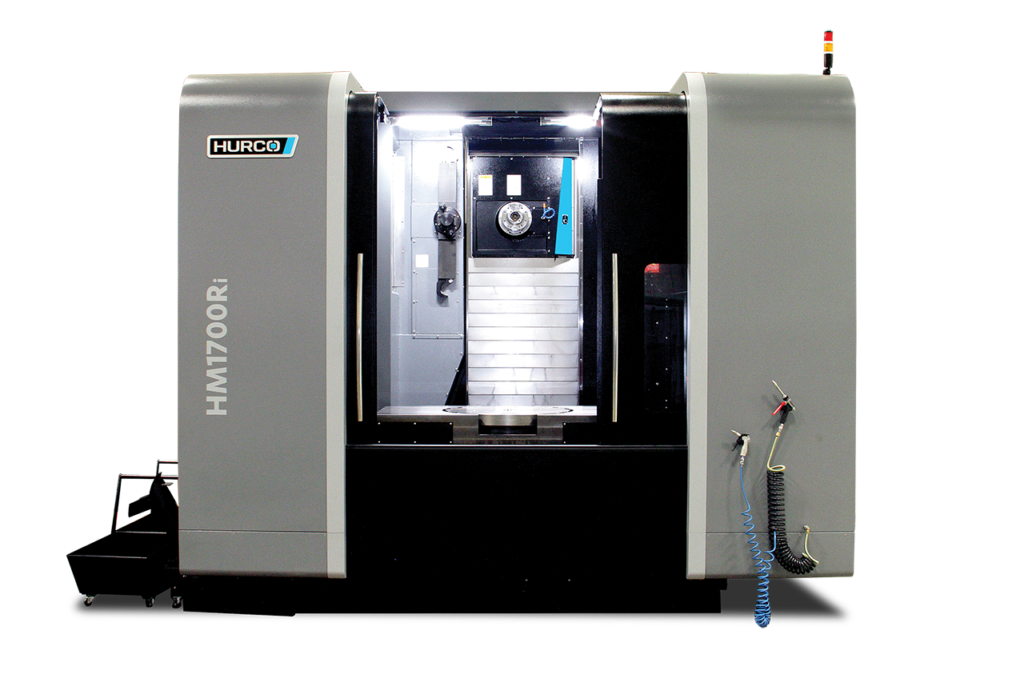

Hurco HM1700Ri

Horizontal Machining Center

Horizontal Machining Center, HMi Series

The Hurco HM1700i horizontal mill machine is designed for maximum efficiency and is equipped with pre-tensioned, dual ballscrews which results in increased rigidity. The large, front and side access doors allows for easy operator use. It is fully equipped with an 8,000 rpm dual winding spindle for both high and low end torque operations. With fast rapids, large work cube, and unique frame design on the HM1700i, it allows complex production parts to be machined efficiently and accurately.

Main Specs:

- Travel: 67″ x 47″ x 35″

- Table Size: 65″ x 33″ with 31.5″ Rotary Table

- Spindle: 8,000 RPM, 328.3 ft/lbs

- Tool Capacity: 30 CAT50

- Machine Weight: 42,550 lbs

Features

Standard

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- Wedge-locked Heavy duty Linear Rails for All Three Axes

- Direct Drive Z axis with Regenerative Brake – No Counterbalance

- Double-Nut Pre-Tensioned Ballscrews

- 8,000 RPM Spindle

- Yaskawa Sigma V AC Servos

- Fast 1,181 ipm Rapid Traverse Rates (X,Z) and 787 on Y

- Electric Swing-arm 30 Station ATC – Random Access

- Full Enclosure with Large Access Doors

- Door Safety Interlocks / ANSI B11.23

- Metal Telescopic Way Covers

- Automatic Central Lubrication System

- Power Cabinet Heat Exchanger

- Modular One-Piece ITX Control Rack

- 2.7GHz Dual Core Processor

- 4GB RAM Memory

- 128GB Solid State Hard Drive

- 12 Months Parts and Labor Warranty (24 months Control and Drives)

Hurco HM1700Ri Machine Specifications

| Travel | |

| X-Axis | 67″ |

| Y-Axis | 47″ |

| Z-Axis | 35″ |

| B-Axis | 360º |

| Table | |

| Dimensions | 65″ x 33″ |

| Max Load | 6,614 lbs |

| T-Slots | 7 x .7″ on 4.92″ Centers |

| Rotary Table | 31.5″ diameter |

| Spindle | |

| Spindle Speed | 8,000 RPM |

| Spindle Torque | 298 ft/lbs |

| Spindle Motor | 35.4 HP |

| Coolant Thru Spindle | Optional |

| Spindle Taper | CAT50 |

| Feed Rate | |

| Rapid Traverse (X/Y/Z) | 1,181/787/1,181 ipm |

| ATC | |

| Capacity | 30 Tools |

| Max. Tool Diameter | 4.7″ |

| Max. Tool Length | 11.8″ |

| Requirements | |

| Air Pressure | 5 CFM @ 80-100 psi |

| Machine Net Weight | 42,550 lbs |