Hurco HTM30i

Toolroom Mill

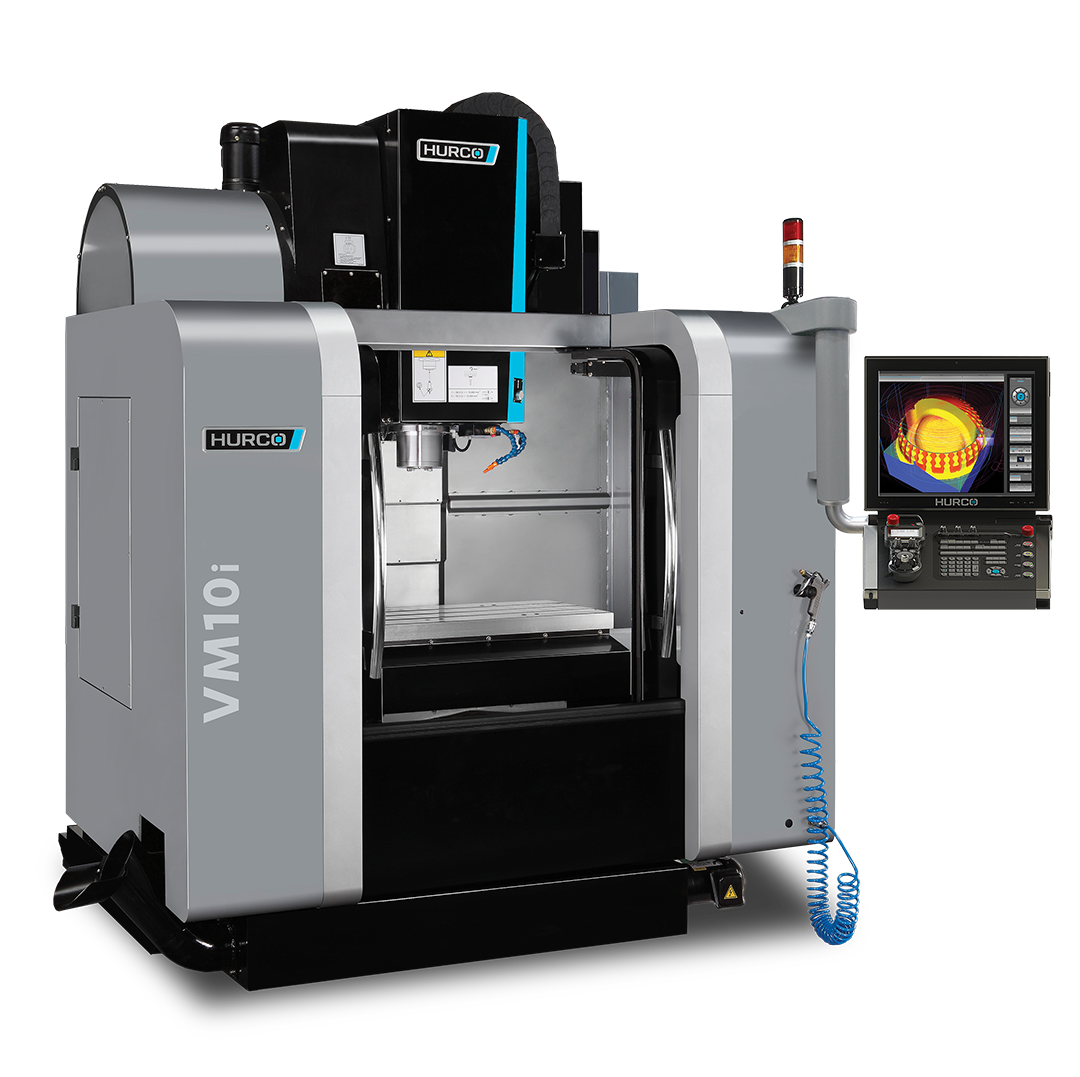

Hurco Tool Room Mill

The Hurco HTM tool room mill offers a compact footprint, and absolutely the best value on the market. The open-bed design allows for easy access to table for ease of use. The entry level tool room is a perfect fit for many applications and offers performance and simplicity.

Main Specs:

- Travel: 30″ x 17″ x 18″

- Table Size: 35.4″ x 16.1″

- Spindle: 8,000 RPM, 42 ft/lbs @1,500

- Tool Capacity: 16 CAT40

- Machine Weight: 7,760 lbs

Hurco’s Control Gets You from Print to Part Faster

Even though the toolroom machine has a single screen control versus the dual-screen found on the higher performance machining centers, you still get the benefit of all the powerful features that maximize productivity. Some favorites are listed below.

Even though the toolroom machine has a single screen control versus the dual-screen found on the higher performance machining centers, you still get the benefit of all the powerful features that maximize productivity. Some favorites are listed below.

DXF Transfer is the easiest and fastest way to get the part program into the control. Simply import the CAD image, select the desired features, and the WinMax control automatically creates the program. Eliminate data entry mistakes and save valuable time.

AutoCalc automatically trigs out the missing information from a print. No trig or calculator needed.

Program Interrupt stops cutting, retracts the tool, and allows you to jog any axis. With just two keystrokes, the tool resumes cutting right where it left off. Just like a true program interrupt button should behave.

Concurrent Programming makes it possible to program the next part while the machining center is running another part without interrupting the cycle.

Technology never stops and neither do we. Hurco engineers continually find ways to develop software features that increase customer profitability. A few of the most recent control features are highlighted below.

UltiMotionTM reduces cycle time by up to 30% while significantly increasing surface finish quality.

UltiMonitorTM allows remote monitoring of your machine from any web browser. See the control screen or video from a USB camera at the machine.

Absolute Tool Length allows tool setup to be independent from the part and machine, which means the tool information only needs to be captured once allowing the tool to be used on other machining centers. Facilitates the use of an offline tool presetter.

Tool Change Optimization is a new feature that analyzes the part program and automatically reduces the number of tool changes by rearranging the program for optimal efficiency.

Features

Standard

- Wedge-locked Heavy duty Linear Rails for All Three Axes

- Precision Ballscrews

- 8,000 RPM Spindle

- CAT40

- Air Purged Chrome-molly Alloy Cartridge Spindle with ABEC Class 7 Bearings

- Fast 500 ipm Rapid Traverse Rates

- 16 pocket carousel ATC

- Work Light

- Metal Telescopic Way Covers

- Rigid Tapping

- Winmax Classic

- Table Guard

- Chip Pan

- Flood Coolant System

- Automatic Central Lubrication System

- Power Cabinet Heat Exchanger

- Modular One-Piece ITX Control Rack

- 2.7GHz Dual Core Processor

- 4GB RAM Memory

- 128GB Solid State Hard Drive

- 12 Months Parts / 6 Month Labor Warranty

Hurco HTM30i Machine Specifications

| Travel | |

| X-Axis | 30″ |

| Y-Axis | 17″ |

| Z-Axis | 18″ |

| Spindle Nose to Table | 4″ – 22″ |

| Table | |

| Dimensions | 35.4″ x 16.1″ |

| Max Load | 992 lbs |

| T-slot | 0.63″ on 3.94 Centers |

| Spindle | |

| Spindle Type | Belt |

| Spindle Speed | 8,000 RPM |

| Spindle Torque | 42 ft/lbs |

| Spindle Motor | 12 HP |

| Spindle Taper | CAT 40 |

| Feed Rate | |

| Rapid Traverse (X/Y/Z) | 500/500/500 ipm |

| ATC | |

| Capacity | 16 Tools |

| Max. Tool Diameter | 4″ |

| Max. Tool Length | 11″ |

| Requirements | |

| Air Pressure | 5 CFM @ 80-100 psi |

| Power Consumption | 23 KVA |

| Machine Net Weight | 7,760 lbs |

| Operating Dimensions | 123″ x 159″ x 110″ |