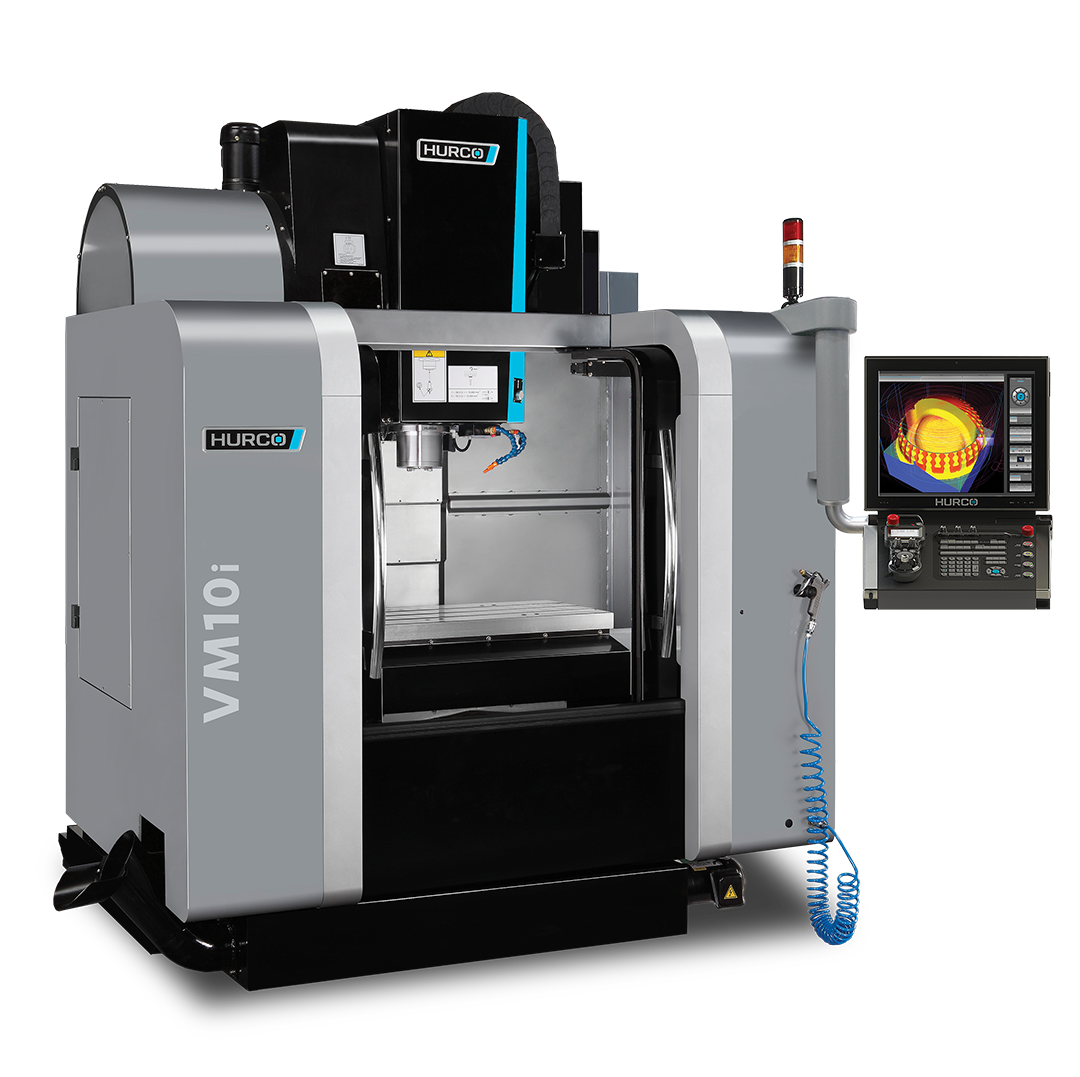

Hurco TMM12i

CNC Lathe – General Purpose Mill Turn

General Purpose Mill Turn Lathes, TMMi Series

The Hurco TMM12i CNC mill turn machine is a true slant-bed lathe equipped with live tooling. These mill turn lathes are the perfect way to make small to medium lot sizes that require turning and secondary milling/drilling operations profitable. The rigid one-piece machine base casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting. Save time with one setup and you won’t lose accuracy due to refixturing.

Main Specs:

- Travel (X,Z): 12″ x 40″

- Max. Turning Diameter: 14.2″

- Max. Turning Length: 36.9″

- Max. Bar Capacity: 4.09″

- Spindle: 2,800 RPM, 333 ft/lbs @380

The most significant advantage the Hurco TMM mill turn machines is the simplified programming and operation via the control. Learn more about mill turn control features. Beyond the control technology, the TMM mill turn machines have multiple design features that prove valuable for mill turn applications.

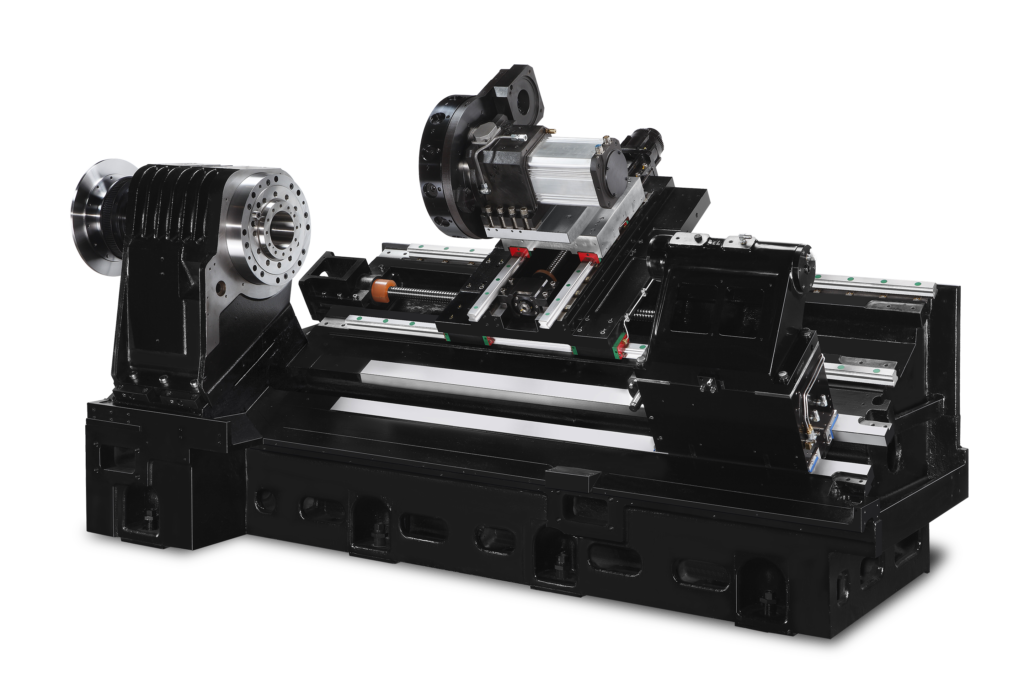

- Design + Construction: We use thick-walled, fine-grain cast iron for the major structural assemblies (base, head stock, and cross slide). The rigid one-piece machine base casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting. The box type cross slide ensures the turret remains rigid and stable even during the most rigorous cycles. We also use extra wide linear guide ways that are strategically spaced to provide excellent support to the cross slide.

- Fast, Servo Turret: The slotted tool turret is designed to provide fast and accurate tool indexes. You can use any combination of ID and OD tool holders. The turret uses a large cervic coupling for accurate location and clamping.

- C-Axis: The C-Axis programs to .001 degree and it is standard on the Hurco lathes with live tooling—not an additional charge like competitor models.

Hurco’s Control Gets You from Print to Part Faster

Hurco engineers have made sure the control of the TMM mill turn lathes has features that simplify 3-axis turning. For example, when programming holes on the face of a part, you can choose to program in polar or rectangular coordinates. Additionally, the threading cycle performs multi-pass threading for outside diameter (OD) and inside diameter (ID) threads. The control simplifies threading—you can easily set spring passes, decreasing depths, and multiple starts found in complex threads on one screen.

As with all Hurco machine tools, our integrated control can be programmed on the shop floor with Hurco’s patented conversational programming or industry standard NC. Our control lets you choose the best method of programming for your shop and for each individual job. Additionally, the easy-to-use touch screen provides helpful setup and verification graphics that show cuts on the screen before they are executed—virtually eliminating wasted materials and potential machine crashes.

Additionally, the Hurco mill turn machines have all of the popular productivity features found in TM and TMX lathes.

DXF Transfer: Eliminates the need to hand code complex profiles.

3D Verification Graphics: Half and quarter views with semi-transparency to see more of the toolpath information especially inside the part.

Auto Tool Nose Radius Compensation: Eliminate the need to use trigonometry to compensate for the tool nose radius on start and end positions of a toolpath.

Conversational Programming: Our founder invented this intuitive, straightforward programming method that leverages the power of technology to do what software does best—the redundant and mathematical tasks—and leaves the machining expertise to you. Features such as AutoCalc, Constant Surface Speed, and Diameter or Radius Programming, are just a few examples of how conversational simplifies complex processes.

ISNC (G Code) Programming: While we’re known for our conversational programming, the NC side of our control accepts FANUC formatted programs, including macros, and is compatible with the most utilized CAM systems.

Premium Components + Expert Design

At Hurco, mill turn machines are built for increased rigidity with an extra wide saddle and large Z-axis rails. You can be assured our TMM mill turn machines have the premium components and rigidity you need.

- One-piece bed casting for maximum rigidity.

- Ergonomic design features make each process more efficient.

- Convenient front access to chuck and tailstock pressure controls.

- Front loading coolant tank and chip conveyor design to minimize maintenance.

- The 30-degree true slant bed design promotes larger turning capacity in addition to efficient chip removal.

- Component isolation system minimizes heat dissipation and protects the spindle head to combat spindle growth.

- Chip management features protect internal components

- Telescopic way covers

- Inside door track

- Washdown and air guns

- Adjustable brass coolant nozzles

Premium Components

The VDI servo turret provides quick change tooling and fast indexing, features large, curvic coupling for superior rigidity, and makes all stations live-tool capable.

The short, live-tool drive train generates less heat, and provides more torque transfer to the tool, higher reliability, and quieter operation.

Advanced spindle technology with high output spindle motor. Additionally, the spindle motor is strategically designed for easy access and easy maintenance

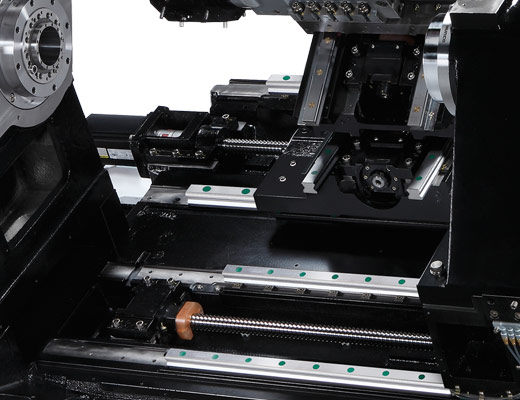

Guide ways: The guide mechanism for the axes is fitted with precision linear ball rails. Our linear rails are built with the same precision grinding technology used in the manufacture of bearings because this technology provides superior acceleration and deceleration performance at full load-carrying capacity in all directions. Using Finite Element Analysis (FEA) technology, the size and spacing of the linear ball rails have been carefully matched to the machine’s static (precision boring) and dynamic (cutting and traversing) operating requirements. Each bearing block is independently and automatically lubricated to promote long life.

Ball Screws: For feed drive elements, Hurco only uses premium, quality designed, pre-tensioned ball screws. With up to 98% efficiency, the re-circulating ball nut ensures low friction power transmission from the screw to the slide. This guarantees the combination of high accuracy, high rapid traverse rates, and high feed thrust. Large diameter X-axis and Z-axis double nut ball screws are hardened and ground, centered between the guide ways, and anchored at both ends with pre-loaded ABEC-7 precision class angular contact thrust bearings. This combination prevents backlash and provides outstanding positioning repeatability with virtually no thermal growth.

Axis Drives: To maintain a leading edge in motion control technology all ball screws are driven by Yaskawa or Rexroth servo systems with closed-loop adaptive tuning and high-resolution feedback to obtain the utmost in system performance and reliability. The AC servo motors are direct-coupled to the ball screws for the highest level of accuracy. The brushless AC servo drive motors provide high torque to inertia ratio for the axis drives. The X and Z axis motors deliver impressive torque for peak thrust during heavy cuts.

Features

Our control technology is the greatest advantage of our lathes because the technology we develop yields the greatest opportunity for our customers to increase profitability via increased productivity. With large capacity memory, a fast processor, and multiple control features that minimize setup time, you will benefit from a control that helps you get from print to part faster.

Standard

- Heavily Ribbed Fine-Grade Cast Iron Frame Optimized with Finite Element Analysis (FEA)

- True slant bed

- Heavy duty Linear Rails for X, and Z axis

- Double-Nut Pre-Loaded Ballscrews

- 2,800 RPM Cartridge Spindle

- High Pressure Coolant 300 psi

- A2-11 Series Spindle Nose

- Brushless AC Servos

- Fast 748/945 ipm Rapid Traverse in X and Z

- 12 Station Servo Tool Turret

- .45 Second Tool Index Time (Adjacent)

- Large Work Cylinder

- Conversational Turning Programming

- Constant Surface Speed

- USB 2.0 Port

- Text Input Capabilities

- Work End Signal Light

- Door Safety Interlocks / ANSI B11.22

- Wide Enclosure Door Openings

- Air and Coolant Gun Assemblies

- Chip Conveyor

- Shortest Path Tool Turret Indexing

- Tool Pre-Setter

- Spindle Chiller

- Auto Interrupt Cycle

- Spindle Air and Coolant Blast

- 3-Jaw Chuck including Soft Jaws

- Flood Coolant Assembly

- Automatic Central Lubrication System

- Modular One-Piece ITX Control Rack

- 2.7GHz Dual Core Processor

- 4 GB RAM Memory

- 128 GB Solid State Hard Drive

- 12 Months Parts / 6 Months Labor Warranty

Hurco TMM12i Machine Specifications

| Travel | |

| X-Axis | 12″ |

| Z-Axis | 40″ |

| Distance Between Centers | 44.7″ |

| Swing Over Bed | 26.8″ |

| Swing Over Cross Slide | 20.1″ |

| Max. Turning Diameter | 14.2″ |

| Max. Turning Length | 36.9″ |

| Spindle | |

| Spindle Nose | A2-11 |

| Spindle Speed | 2,800 RPM |

| Spindle Torque | 333 ft/lbs |

| Spindle Motor | 24 HP |

| Spindle Chuck | 12″ |

| Spindle Bore Diameter | 4.62″ |

| Motion | |

| Rapid Feed Rate (X/Z) | 748/945 ipm |

| Servo Tool Turret, Duplomatic DM-DT25: | |

| Capacity | 12 / Axial |

| Rotation | Bi-Directional |

| Tool Shank | 1.26″ x 1.26″ |

| Max. Boring Bar Diameter | 1.97″ |

| Requirements | |

| Power Consumption | 37 KVA |

| Machine Net Weight | 16,758 lbs |

| Operating Dimensions | 190″ x 132.5″ x 88.1″ |