iFP KP50 H/MA

Vacuum Parts Cleaning Machine – Basic Series

High Volume

A popular, single basket, iFP platform ideal for mid-volume parts manufacturers demanding superior part cleaning performance and efficiency. Consider the KP50 if you wish to place individual washers in multiple departments within a large facility.

iFP high performance Vacuum parts washers provide a self-contained, highly efficient and environmentally friendly solution to meet your most demanding parts washing requirements.

iFP systems can safely use the industry’s leading solvents, guaranteeing the best cleaning results for parts manufactured in oil or water base cutting fluids, especially those presenting the most challenging internal or external features.

Superior solvent distillation, filtration and oil separation designs combine to assure the most miniscule solvent consumption, reduced labor and highly reduced waste disposal / handling costs.

Features

Standard Features

- Vacuum technology providing a Green, air tight, closed loop cleaning platform.

- Superior, self-contained solvent distillation system allowing continual solvent recycling with minuscule consumption.

- Independent oil separation system and tank delivering the high level of separated oil purity.

- Multi tank solvent design.

- Vacuum dry cycle assuring dry part certainty with accelerated dry times.

- Compact footprint.

- 3 vacuum pumps for high performance and short cycle times.

- Simple, memorized programmable wash cycles including programmable basket oscillation or full rotation.

- Chip filter cartridge system resulting in clean dry chips.

- Modem connection for efficient, real time Gosiger service assistance.

- Standardized basket designs with wash loads to 110 lb.

- Ideal for cleaning parts produced in oil or water based coolants.

Common Options

- Ultrasonics.

- Secondary filter(s) for ultra-fine filtration and bypass operation.

- 3rd solvent tank for ensuring pure solvent delivery in final wash cycle.

- Application specific basket designs.

- Automatic door.

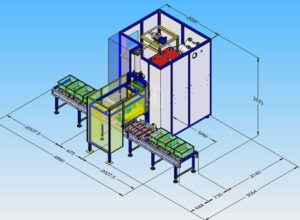

iFP KP50 H/MA Machine Specifications

| Number of Baskets per Wash Cycle | 1 |

| Basket Size | 11.9″ x 7.9″ x 17.7″ |

| Machine Dimensions | 70″ x 103″ x 70″ |

| Chiller Size | 5 ton |

| Solvent Capacity | 106 Gallon |

| Wash Cycles Per Hour | 4 to 8 |

| Chamber “Max. Load Weight” | 110 lbs |

| Machine Weight | 4,000 lbs |