Small Series Basic Series Large Series

iFP

iFP high performance Vacuum parts washers provide a self-contained, highly efficient and environmentally friendly solution to meet your most demanding parts washing requirements.

iFP systems can safely use the industry’s leading solvents, guaranteeing the best cleaning results for parts manufactured in oil or water base cutting fluids, especially those presenting the most challenging internal or external features.

Superior solvent distillation, filtration and oil separation designs combine to assure the most minuscule solvent consumption, reduced labor and highly reduced waste disposal / handling costs.

iFP Vaccum Part Washers

Small Series – Small, single basket cleaning platform. KP30

Basic Series – Single and double basket capacity with quality technology. KP50 / KP100

Large Series – Large three and four basket model with high performance capabilities. KP150 / KP200 / KPMax

THE BEST TECHNOLOGY ON THE MARKET

The KP series washing machines, thanks to the vacuum-modified cycle of washing with vacuum values of up to 1 millibar and the extensive standard and optional equipment, represent the best washing technology on the market.

THE BEST ENVIRONMENTAL QUALITY

The KP washing machines working totally under vacuum ensure that at the end of the treatment no residual of washing liquid is present on the pieces or released in the environment .

THE BEST PRODUCTIVITY

KP washing machines, thanks to the reduction in cycle time, allow a 100% increase in production capacity and a 50% reduction in electricity consumption.

THE BEST QUALITY OF WASHING

KP washing machines constantly ensure the best metal washing results whatever the degree of contamination and the type of details, even in the case of deep blind drilling.

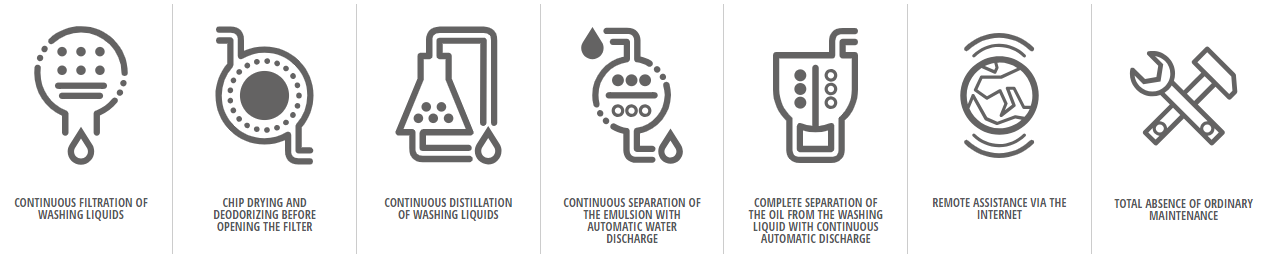

THE BEST MANAGEMENT OF THE WASHING LIQUID

The KP washing machines allow to drastically reduce the consumption of washing liquid up to a few liters per year and eliminate the need for addition of chemical products (stabilizers).

THE BEST MANAGEMENT ECONOMY

The KP washing machines allow to completely separate the oil from the washing liquid and to reuse it in the production cycle with great economic advantage. The chip is also separated according to the type of material and daily maintenance is eliminated .

STANDARD EQUIPMENT

Fully Stainless Construction

Plant Vacuum Tight For Vacuum Cleaning

Washing Liquid Pumps High Pressure

Vacuum Pumps

Spraying a Variable Turbulence System

Cryogenic Abatement System

Distiller Stripping Sludge

Hermetic of Washing Liquid Loading / Unloading System

Washing Liquid Filtration

Double Washing Liquid Storage Tank

Touch Screen Operating Panel

Remote Assistance Via Internet

OPTIONAL EQUIPMENT

Ultrasonic Transducers For Ultrasound Washing

Third Washing Liquid Tank

Protective Agent Application Group

Additional Filtration Units

Automatic Load Handling Systems

Automatic Load Recognition Systems